Since the early 1900s nickel plating of shell casings have been the norm for ammunition used in revolvers for law enforcement. Until the introduction of Techni-crom™, nickel shell casing performance lagged behind modern firearm performance. Today’s modern defense firearm actions are more demanding than ever before with reduced cycle times and higher rates of fire. In addition, hot +P and magnum loads often used in critical and self-defense applications produce internal chamber pressures beyond standard SAAMI loadings. Techni-crom™, is the first shell coating system engineered to improve both the function and reliability of ammunition for critical applications.

Enhanced Lubricity

Techi-crom™ combines Advanced Plating Technologies’ proprietary Ducta-bright 7a nickel process with anadvanced top coat to provide enhanced dry-film lubricity and greatly improved corrosion resistance over raw brass or traditional nickel plated shell casings. The reduction of friction between the casing wall and the firearm’s chamber and breech is key to ensuring the most consistent and dependable firearm cycling, including semi-automatic actions.

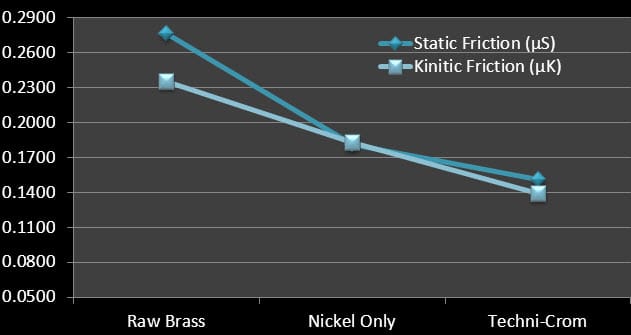

Techni-crom™ provides a proprietary dry-film technology that reduces both static (resting) and dynamic (sliding) coefficients of friction by over 40% compared to a standard brass casing when tested by an independent metallurgical testing lab*.

Brilliant “Bright Blue” Color

Techni-crom™ offers a brilliant chrome-like appearance that is free of the gray, dull cast of traditional nickel plating.The appearance enhances the luster of the finish and helps make premium product stand out at point of purchase for critical ammunition lines. Techni-crom™ retains its luster over extended storage and will not show appreciable tarnishing or darkening over time as can raw brass or nickel. Techni-crom™ cleans up with ease after reloading, making it an excellent choice for applications where reloading is likely.

Unmatched Duplex Corrosion Resistance

The reliability and function of ammunition is of paramount concern in applications where repeated and harsh environmental exposure as well as extended storage occurs. In self-defense, law enforcement, safari-grade applications, the factors of moisture, temperature and even salt water exposure are ammunition design considerations that should not be overlooked. Traditional brass casings do little to prevent the corrosion that can occur when repeatedly exposed to corrosive conditions. Traditional nickel systems offer only a thin, single layer of protection over that of standard brass. The Techni-crom™ process provides a duplex (two layer) system that enhances corrosion resistance of the shell casing by over four times that of raw brass when tested in the accelerated salt fog corrosion test per ASTM B117. There is no other coating system on the market that provides the enhanced duplex corrosion protection that Techni-crom™ imparts. The reliable function of ammunition in harsh environments is not something that can be gambled with when lives or personal security are at stake.

* Gaynes Labs, Incorporated Job No. 13625: Coefficient of Friction Testing of Shell Casings