![]()

Until the development of the Ducta-bright 7a® process, nickel plating of shell casings often limited the number of reloads as compared to raw brass. It was claimed that nickel plating of brass shell casings “embrittled” the brass thereby making it less preferable for reloaders despite the ease of cleanup that nickel plating affords. In addition, ammunition engineers raised concern of using nickel plating in very hot +P or magnum loads – especially in deep-drawn casings – where it was thought that nickel plating of such loads could result in once-fired casing cracking or failures.

Such preexisting industry concerns conflict with the metallurgy involved in nickel plating of brass casings. Classic C260 cartridge brass (70% copper, 30% zinc) is not susceptible to hydrogen embrittlement nor is there any chemistry employed in traditional nickel plating processes that is known to embrittle brass such as ammonia. Due to repeated inquiries regarding these design concerns by engineers within the ammunition industry, Advanced Plating Technologies set forth to investigate nickel plating of brass casings further. The aim was to try and determine if these deleterious effects actually occurred and if they did, establish root cause and develop a system that would mitigate these deposit flaws.

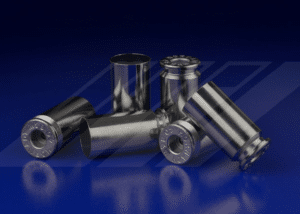

Nickel Plating of Shell Casings – Ducta-bright 7a® Nickel Development

Of the 40 trials lots analyzed, four finalist lots emerged from the JLB impact testing. These lots were field tested in live firing trials where the casings were loaded, fired and reloaded until the casings cracked during reloading. The result of this exhaustive study was that the 7th lot, method A was found to be functionally superior above all other lots. The process parameters from this lot became the Ducta-bright 7a® process. Today APT deposits this nickel system on millions of casings weekly within critical commercial and defense applications.

Nickel Plating of Shell Casings – Why the Ducta-bright 7a® Nickel Process?

Nickel plating of shell casings offers many functional improvements over raw brass including:

- Enhanced feeding in all actions of firearms;

- Improved corrosion resistance for reliability during extended storage or aggressive field applications;

- No tarnishing of brass when stored in leather holsters or pouches;

- Ease of cleanup after firing to remove carbon and soot prior to reloading.

In the past, ammunition engineers had to weigh the potential benefits of nickel plated casings against the risk of cracking or failures in hot loads such as +P or magnum applications. There is no question that modern critical defense and +P loads stress brass casings further than ever before and reliability of nickel plated brass casings in critical defense applications is paramount in the design consideration. In addition, avid reloaders had to weigh the ease of cleaning nickel plated brass casings against the reduction in reloads afforded by plated brass.

Advanced Plating Technologies’ proprietary Ducta-bright 7a® Nickel process eliminates these concerns for high-performance nickel plated brass casings applications and avid reloaders. The Ducta-bright 7a® Nickel process provides a lustrous nickel deposit that can withstand even the most aggressive +P loading and will afford virtually as many reloads as a raw brass casing. Simply put, there is no other nickel system available today that provides the functional and durability improvements as does Advanced Plating Technologies’ Ducta-bright 7a® Nickel process.

[/bs_citem]

[/bs_collapse]