Passivation of Stainless Steel Properties

Stainless steel or corrosion-resistant steel (CRES) is defined as a steel alloy with a minimum of 11% chromium content by weight. Many alloys of stainless steel include substantial nickel to further enhance the corrosion resistance. In general, stainless steel is broken down into three main groups based upon the alloying elements and

The reason for the stain-less nature of stainless steel is due to the formation of a thin, adherent and passive (nonreactive) film of nickel & chromium oxides that forms a barrier to prevent further surface corrosion of the product. This is in stark contrast to iron oxide (red rust) that forms on plain carbon steel products. Iron oxide is a loose, scaly oxide that easily falls away to allow the formation of additional iron oxide, thereby perpetuating the corrosion reaction.

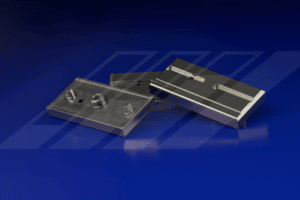

When stainless steel products are manufactured, free iron is transferred to the surface of the material from the steel cutting, stamping and forming tools used in the manufacturing process. Free iron can also be imparted on the surface by polishing or blasting operations that utilize the same polish or blast media between both mild steel and corrosion resistant steel grades. Free iron readily oxidizes, forming visible rust on the surface of the product. Passivation is a chemical treatment with a specific acid formulation that removes free-iron or other surface contamination from the stainless steel while simultaneously promoting the formation of a passive chromium/nickel oxide layer to act as a barrier to further corrosion.

It is important to note that stainless steel is corrosion resistant but not corrosion proof. The degree of corrosion resistance of a stainless steel alloy is a function of the alloying composition, heat treatment, internal stresses and passivation treatment. An example of this phenomenon is 303 free-machining stainless steel which has notably less corrosion resistance than 304 stainless steel due to the higher concentration of sulfur and phosphorous that imparts the desired machinability of the 303 grade. As a general rule, the higher the nickel and chromium content in the alloy, the more corrosion resistance it will have.

Passivation of Stainless Steel – Advanced Plating Technologies’ Capabilities

Specifications:

ASTM A967

AMS 2700

QQ-P-35

ASTM 380

ASTM F86

AMS 2700

ISO 16048

Most Company Specifications

Types:

Precision Medical-Grade Passivation

Commercial Passivation

A-A-A (Alkaline-Acid-Alkaline) Passivation

Stainless Steel Grades Passivated:

Austenitic Grades (All 200 & 300 series)

Ferritic Grades (Part of 400 series and low carbon alloys)

Martensitic Grades (Part of 400 series and higher carbon alloys)

Medical & Exotic Alloys: Titanium, MP35N, 316LVM, Cobalt-Chromium, Inconel, Nickel-Alloys (Nickel 200), Kovar, Invar

Part Size Limitations: 24 Inches x 28 Inches x 10 Inches

Heat Treatments Offered:

Hydrogen Embrittlement Bakes

Stress Relieving Bakes

High Temperature Bakes up to 750F

Methods:

Nitric Acid Passivation

Citric Acid Passivation

CitriSurf Passivation

A-A-A (Alkaline-Acid-Alkaline) Passivation (Citric or Nitric)

Passivation of Stainless Steel Specifications

Advanced Plating Technologies, offers passivation all methods listed within ASTM A967, AMS 2700 and QQ-P-35. In addition, APT can meet the requirements of any company-specific nitric or citric acid stainless steel passivation methods. Our company also provides passivation of stainless steel to the Carpenter A-A-A process to passivate difficult stainless steel alloys including high-sulfur free machining 303 or 416 alloys as well as high chromium alloys such as 440 stainless (reference: A-A-A Passivation Methods article in our Metal Finishing White Papers section). Inhibited passivation solutions are available to maintain bright surfaces of stainless components such as machined faces and centerless ground 303 or 416 stainless steel shafts.

Unfortunately, very few part prints indicate the specific method to be employed. This opens the door for finishing job shops to use any convenient method they have available resulting in a part that has been passivated but is not truly passive (reference: My passivated “stainless” steel product is exhibiting corrosion, how can this be prevented? in our Plating Topics section).

APT’s extensive experience in passivation ensures that the correct passivation method will be selected to match the specific stainless steel grade. Advanced Plating Technologies provides full in-house testing services to certify the performance of our stainless steel passivation including high humidity, salt spray per ASTM B117, potassium ferricyanide

The most common stainless steel passivation specifications certified by Advanced Plating Technologies are ASTM A967, AMS 2700 and QQ-P-35. APT can also certify passivation to ASTM A380, ASTM F86, AMS 2700C, ISO 16048 as well as most company-specific passivation specifications. A summary of stainless steel passivation techniques per the common ASTM, AMS and Mil specs is as follows:

Passivation of Stainless Steel to ASTM A967

Five nitric and citric methods are listed as follows:

Nitric 1: 20-25 v% Nitric Acid, 2.5 w% Sodium Dichromate, 120-130F, 20 Mins minimum

Nitric 2: 20-45 v% Nitric Acid, 70-90F, 30 Mins minimum

Nitric 3: 20-25 v% Nitric Acid, 120-140F, 20 Mins minimum

Nitric 4: 45-55 v% Nitric Acid, 120-130F, 30 Mins minimum

Nitric 5: Other combinations of temperature, time, and acid with or without accelerants, inhibitors or proprietary solutions capable of producing parts that pass the specified test requirements

Citric 2: 4-10 w% Citric Acid, 120-140F, 10 Mins minimum

Citric 3: 4-10 w% Citric Acid, 70-120F, 20 Mins minimum

Citric 4: Other combinations of temperature time and concentration of citric acid with or without chemicals to enhance cleaning, accelerants or inhibitors capable of producing parts that pass the specified test requirements.

Citric 5: Other combinations of temperature time and concentration of citric acid with or without chemicals to enhance cleaning, accelerants or inhibitors capable of producing parts that pass the specified test requirements. Immersion bath to be controlled at pH of 1.8-2.2

Five testing methods to validate passivation services are provided as follows:

Practice A – Water Immersion Test

Practice B – High Humidity Test

Practice C – Salt Spray Test

Practice D – Copper Sulfate Test

Practice E – Potassium Ferricyanide-Nitric Acid Test

A table of recommended nitric acid passivation methods is provided in the Appendix that correlate Nitric 1 through 5 methods to the specific stainless steel alloy grade. No such reference is provided in the specification for Citric 1 through 5 methods.

Passivation of Stainless Steel to AMS 2700

AMS 2700 covers passivation to both nitric and citric method

Method 1 – Passivation in Nitric Acid (see types below)

Method 2- Passivation in Citric Acid (4-10w% Citric Acid, various temperature/time ratios are offered and additional wetting agents and inhibitors are acceptable)

The following types may be specified for Method 1:

Type 1 – Low temperature nitric acid with sodium dichromate (20-25v% nitric, 2-3w% sodium dichromate, 70-90F, 30 mins min)

Type 2 – Medium temperature nitric acid with sodium dichromate (20-25v% nitric, 2-3w% sodium dichromate, 120-130F, 20 mins min)

Type 3 – High temperature nitric acid with sodium dichromate (20-25v% nitric, 2-3w% sodium dichromate, 145-155F, 10 mins min)

Type 4 – 40v% nitric acid for free machining steels (38-42v% nitric, 2-3w% sodium dichromate, 70-120F, 30 mins min)

Type 5 – Anodic, for high carbon martensitic steels (20-25v% nitric, 2-3w% sodium dichromate, 70-90F, 2 mins min, part anodic at 3-5 volts)

Type 6 – Low temperature nitric acid (25-45v% nitric, 70-90F, 30 mins min)

Type 7 – Medium temperature nitric acid (20-25v% nitric, 120-140F, 20 mins min)

Type 8 – Medium temperature, high nitric acid concentration (45-55v% nitric, 120-130F, 30 mins min)

3.1.3 Method 2 – Passivation in Citric Acid

3.1.3.1 Bath Composition

Parts shall be immersed in an aqueous solution of 4 to 10 percent citric acid, with additional wetting agents and inhibitors as applicable.

3.1.3.2.1 Temperature

Bath temperature shall be 70 to 160F (21 to 71C) with an immersion time of not less than 4 minutes for baths operating over 140F (60C), not less than 10 minutes for baths operating in the 120 to 140F (49 to 60C) range, not less than 20 minutes for baths operating in the range of 100 to 119F (38 to 48C) or not less than 30 minutes for baths operating below 100F (38C).

-

- 4-10w% Citric Acid, 140-160F, 4 Mins Min

- 4-10w% Citric Acid, 120-140F, 10 Mins Minimum

- 4-10w% Citric Acid, 100-119F, 20 Mins Minimum

- 4-10w% Citric Acid, 70-100F, 30 Mins Minimum

Where no type is specified, the processor may use any of the listed types that meet the requirements given within AMS 2700.

The following Classes are provided for testing within AMS 2700 (if no class is defined, Class 2 shall apply):

Class 1 – Testing not defined or as specified by the customer, test per 4.3.1 sampling plan

Class 2 – Testing shall be one part per lot

Class 3 – Frequency of testing shall be on a periodic basis

Class 4 – Frequency of testing defined by 4.3.4 sampling plan (testing previously defined by QQ-P-35)

Various corrosion resistance tests are defined within AMS 2700. However, it is noted that certain alloys such as high carbon alloys with 0.85% carbon or more (such as 440C) are exempt from various testing requirements due to false positives that can result. Parts shall meet one or more of the following tests:

- Humidity Test

- Water Immersion

- Copper Sulfate Test

- Salt Spray Test

Table 4 within AMS 2700 provides a comprehensive summary of both nitric and citric acid methods that can be applied as a function of alloy. This table is more comprehensive than those listed in either ASTM A967 or QQ-P-35.

Passivation of Stainless Steel to QQ-P-35

QQ-P-35 does not cover citric acid passivation services. Four active nitric acid passivation services are covered as follows (four inactive methods have been withdrawn):

Type I – Withdrawn

Type II – 20-25 v% Nitric, 2-2.5 w% Sodium Dichromate, 120-130F, 20 Mins minimum

Type III – Withdrawn

Type IV – Withdrawn

Type V – Withdrawn

Type VI – 25-45 v% Nitric, 70-90F, 30 Mins minimum

Type VII – 20-25 v% Nitric, 120-150F, 20 Mins minimum

Type VIII – 45-55 v% Nitric, 120-130F, 30 Mins minimum

Four testing methods to validate passivation services are provided as follows:

4.4.1.1 – Water Immersion Test

4.4.1.2 – High Humidity Test

4.4.2.1 – Salt Spray Test

4.4.2.2 Copper Sulfate Test

A table of recommended nitric acid passivation services is provided in the Appendix that correlate Type II, VI, VII & VIII methods to the specific stainless steel alloy grade.

Want to learn more about our Passivation Services?

Check out our blog on Nitric vs Citric Acid Passivation.

My passivated “stainless” steel product is exhibiting corrosion, how can this be prevented?