Black Electroless Nickel Plating Services – Tacti-Black® Electroless Nickel

We do not service personal or decorative projects

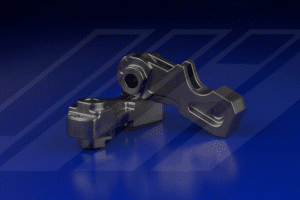

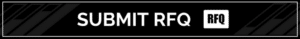

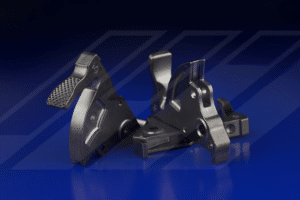

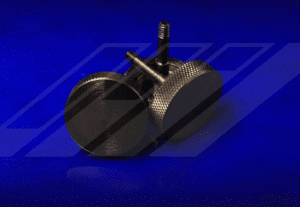

Black electroless nickel plating combines the same exceptional deposit properties of traditional electroless nickel plating but with conductive, black surface finish. Advanced Plating Technologies offers a proprietary black electroless nickel plating – Tacti-black® electroless nickel – which has become the industry standard in black electroless nickel plating. It combines the exceptional lubricity, deposit uniformity, hardness and corrosion resistance of electroless nickel with a fully conductive and uniform black appearance.

Advanced Plating Technology now offers a high performance Tacti-Black® HP+ electroless nickel that offers a darker, more matte black appearance with enhanced corrosion resistance and dry film lubricity. APT’s black electroless nickel plating is currently utilized in a wide range of industries including the firearm, defense, interconnect, telecommunications and aerospace industries.

Black Electroless Nickel Plating – Tacti-Black® Electroless Nickel Properties

APT’s Black electroless nickel plating process produces a deposit that is fully conductive and can be soldered or brazed to make it suitable for interconnect, electronics and EMI grounding/shielding applications. It provides good temperature stability suitable for service temperatures up to 600F with short duration exposures up to 700F. It provides the perfect deposit uniformity of traditional electroless nickel with tolerances of +/- 0.0001 inches per side possible.

A brief summary of the deposit properties for APT’s black electroless nickel plating is provided below:

- Black Electroless Nickel Plating, Tacti-Black® High Phosphorus (>10% P): Semi-bright in luster, solderable with proper flux selection, non-magnetic, amorphous deposit structure, highly corrosion resistance with adequate deposit thickness, low as-plated stress, excellent choice for heavy build, Rc 48-55 (as plated), 66-70 (with heat treatment)

- Black Electroless Nickel Plating, Tacti-Black® Medium Phosphorus (6-9%P): Bright in luster, solderable with proper flux selection, magnetic, semi-crystalline deposit structure, good corrosion resistance with adequate deposit thickness, moderate as-plated stress, not recommended for heavy build, Rc 58-62 (as plated), 66-70 (with heat treatment)

- Black Electroless Nickel Plating, Tacti-Black® HP+: A proprietary black electroless nickel plating in which a rare earth metal molecular sealer is bonded to the surface which enhances the depth of the black and reduces the luster (brightness) of the finish. With a micro-rough or blasted surface, a nearly matte-black appearance can be achieved. Tacti-Black® HP+ electroless nickel will have improved dry-film lubricity and corrosion resistance but will have increased contact resistance and is not recommended for soldering or bonding applications.

Black Electroless Nickel Plating – Tacti-Black® Appearance

The appearance of the black electroless nickel plating process is a function of the luster of the substrate and the selection of the process. The guidelines below will help with the proper selection and process:

- Bright, Deep Black Appearance: A highly machined or polished substrate with Medium Phosphorous Tacti-Black® Electroless Nickel

- Satin, Charcoal Gray Appearance: A rough, textured or bead blasted substrate with High or Medium Phosphorous Tacti-Black® Electroless Nickel

- Satin to Matte, Black Appearance: A rough, textured or bead blasted substrate with high or medium phosphorous Tacti-Black® HP+ Electroless Nickel. Finish is not recommended for soldering or bonding applications.

Advanced Plating Technologies’ Tacti-black black electroless nickel plating provides excellent wear resistance consistent with traditional electroless nickel. However, the black appearance can be worn through in aggressive wear points such as metal-on-metal sliding contact. Therefore, the application of the finish for high wear applications should be evaluated accordingly.

Black Electroless Nickel Plating – Tacti-Black® Electroless Nickel Capabilities

Specifications:

MIL-C-26074

ASTM B733

AMS 2404

ISO 4527

Most Company Specifications

Finish Type:

Medium Phosphorous

High Phosphorous

Substrates Plated On:

Ferrous: All Ferrous Alloys Including Mild Steel, Stainless Steels, Hardened Steels & Tool Steels

Cuprous: All Cuprous Alloys Including Pure Copper, Copper Alloys Including Tellurium & Beryllium, Brass, Nickel-Silver

Aluminum: All Aluminum Alloys Including Wrought, Cast and Proprietary Alloys (MIC-6)

Exotics: Inconel, Pure Nickel (Nickel 200), Cobalt-Chrome (MP35N), Kovar, Monel, Hastalloy, Monel, Lead

Part Size Limitations:28 Inches x 28 Inches x 10 Inches

Larger pieces may be accommodated in certain instances

Underplates Provided:

Copper

Electrolytic Nickel

Heat Treatments:

Hydrogen Embrittlement Bakes

Methods:

Barrel

Rack

Wire

Vibratory

Selective Loose Piece Plating

Sheet Product (Chemically Milled/Etched Sheets)

Segmented Strips (Frets)