Advanced Plating Technologies, a Milwaukee, WI company, provides innovative and unsurpassed extensive expertise in functional and heavy build copper plating services to MIL-C-14550, AMS 2418 and ASTM B734. Advanced Plating Technologies offers both traditional alkaline cyanide copper plating services as well as non-cyanide alkaline copper plating and high-speed acid copper plating services for a wide range of engineering applications. Our company has precision barrel, rack and vibratory copper plating services which are currently employed in numerous industries including the ammunition, HVAC, power distribution, heat treatment, electronic, telecommunication and fastener industries.

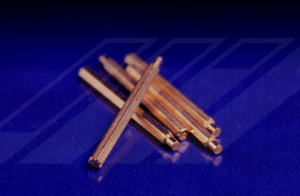

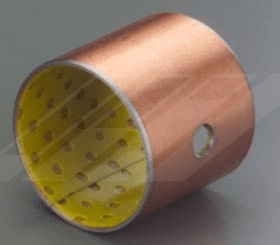

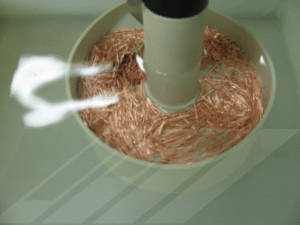

Advanced Plating Technologies copper plating service company can be utilized as a final plate or as an underplate to subsequent deposits. Our company is able to perform tin plating, gold plating, silver plating and nickel plating deposits. APT also provides an unmatched capability in heavy build copper plating services with our company plating thicknesses up to 0.020 inches per side. Applications of heavy build copper plating services include the eddy current drives, lead, tungsten and frangible core bullets (reference Copper Bullet Plating in our Solutions in Surface Finishing section), braze fittings, coinage and heat treatment applications for a stop-off prior to carburizing or nitriding.

Advanced Plating Technologies can offer your company a proprietary tarnish inhibits in copper electroplating services to maintain a clean copper deposit. Unlike traditional “bright dips,” our monatomic inhibit minimizes oxidation and enhances subsequent brazing or soldering applications while ensuring low contact resistance of the copper deposit. This system can also be applied to raw copper components as well to enhance the appearance and functionality of copper deposits. An inhibited copper substrate or deposit will pass 24-hour high humidity testing, maximizing the shelf life and storage of products finished with our copper plating services. In addition, sealed nitrogen packaging can be provided for extended storage of copper deposits without the threat of surface oxidation or discoloration.

Copper Plating Services – Copper Plating Properties

Copper readily forms compounds with elements found in the atmosphere including oxygen, carbon and sulfur. Based upon the oxidation state, available moisture and pH of the environment, the compounds formed can have distinctive blue or green hues (acidic environments) as opposed to dark brown appearance (alkaline environments). An evident example of this phenomenon is the green copper patina (hydrated copper sulfate and carbonate) visible on the Statue of Liberty due to the acidic rain of New York City.

Copper is one of the few metals to occur naturally as an uncompounded mineral. Due to this fact, copper’s use can be traced back as far as 10,000 years ago, to some of the oldest civilizations on record. It is theorized that only gold and meteoritic iron have been utilized by civilizations longer than copper.

For plating applications, copper is commonly used as an underplating to enhance adhesion of deposits, improve electrical properties, impair migration of alloying elements into the final plated deposit, or to improve corrosion resistance of the overall deposit. As a final deposit, copper plating services are used for enhancing the brazing, thermal or electrical conductivity of substrate materials, as a high temperature lubricant, as a heat treatment stop-off, or for jacketing of projectiles. Copper can be plated matte to bright and with a wide range of deposit hardness and ductility.

Copper Plating Services – Advanced Plating Technologies’ Capabilities

Specifications:

MIL-C-14550

ASTM B734

AMS 2418

Most Company Specifications

Purity

Up to 99.0% Pure

Finish Type:

Matte Deposits

Semi-Bright Deposits

Bright Deposits (Mechanical)

Substrates Plated On:

Ferrous: All Ferrous Alloys Including Mild Steel, Stainless Steels, Hardened Steels & Tool Steels

Cuprous: All Cuprous Alloys Including Pure Copper, Copper Alloys Including Tellurium & Beryllium, Brass, Nickel-Silver

Aluminum: All Aluminum Alloys Including Wrought, Cast and Proprietary Alloys (MIC-6)

Exotics: Inconel, Pure Nickel (Nickel 200), Cobalt-Chrome (MP35N), Kovar, Monel, Hastalloy, Monel, Lead

Part Size Limitations: 32 Inches x 30 Inches x 12 Inches

Underplates Provided:

Bright Electrolytic Nickel

Sulfamate Electrolytic Nickel

Electroless Nickel (High or Medium Phosphorous)

Tin, Lead or Tin/Lead

Heat Treatments:

Hydrogen embrittlement bakes

Stress Relieving Bakes

High Temperature Bakes up to 750F

Methods:

Barrel

Rack

Wire

Vibratory

Selective Loose Piece Plating

Sheet Product (Chemically Milled/Etched Sheets)

Segmented Strips (Frets)

Copper Plating Services – Copper Plating Specifications

The two most common copper plating services certified by Advanced Plating Technologies are MIL-C-14550 and ASTM B734. APT also can certify our copper plating services to AMS 2418 as well as most company-specific copper plating specifications. A summary of copper plating services per the MIL and ASTM specs is as follows:

Copper Plating Services to MIL-C-14550

Class 0 – 0.001-0.005 inches minimum deposit thickness

Class 1 – 0.001 inch minimum deposit thickness

Class 2 – 0.0005 inch minimum deposit thickness

Class 3 – 0.0002 inch minimum deposit thickness

Class 4 – 0.0001 inch minimum deposit thickness

Intended Uses per Section 6.1 of MIL-C-14550

Class 0 – for heat treatment stop-off shield

Class 1 – for carburizing shield, decarburizing shield and printed circuit board plated through holes or as specified on the engineering drawing.

Class 2 – for undercoating for nickel and other metals

Class 3 – to prevent basis metal migration into tin layer to poison solderability

Class 4 – 0.0001 inch same as 0.0002 inch

Copper Plating Services to ASTM B734

Class 25 – 25um minimum coating thickness

Class 20 – 20um minimum coating thickness

Class 12 – 12um minimum coating thickness

Class 5 – 5um minimum coating thickness

Class x – Thickness as specified [um]

Copper Plating Services to AMS 2418

Type 1 (Engineering Plating) Shall designate a thickness of 0.0005″ to 0.0007″

Type 2 (Plating for Masking) shall be nominally 0.002″ with no area having a plate thickness of less than 0.0007″