Heavy Build Plating (Electroless and Electrolytic Plating)

A

Heavy Build Plating – What is Heavy Build?

Heavy Build Plating – Why Heavy Build?

Medical Industry: Heavy build gold plating services are utilized within the medical industry to develop a fully pore-free gold deposit for biocompatibility. Typically, biocompatibility begins around 0.0001” per side with applications as high as 0.0003” being common. Advanced Plating Technology offers duplex heavy build gold deposits to further reduce porosity of heavy build gold.

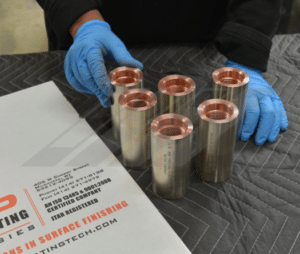

Bearing Industry: Heavy build lead and tin/lead plating services are commonly used in the bearing industry to provide a plated babbitt layer. The soft babbitt deposit offers a lubricous, anti-galling surface that permits embedding of particulate in heavier deposits. Thinner plated babbitt layers in bearings and bushings are commonly used for break-in purposes on highly loaded applications, generally in the range of 3,000 to 8,000 PSI where the surface speed is relatively low. Heavier build coatings are used in loadings up to 3,000 PSI where the thicker coating allows for embedding of contaminants, especially on grooved bearing, bushing or thrust-washer designs.

Petrochemical Industry: Heavy build silver plating and high phosphorus electroless nickel plating services are commonly used in the petrochemical industry where high chemical resistance and/or wear resistance are design concerns. Applications of heavy build high phosphorus electroless nickel to 0.005” per side for natural gas vacuum pumps or sweet crude valve stems have been provided. Heavy build silver plating of over 0.020” per side has been used for resistance to chlorine in chlorine screw compressor bearings.

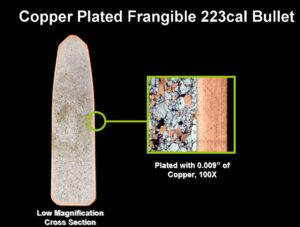

Heat Treatment Industry: Heavy build copper plating is commonly used as a heat treatment stop-off for selective carburizing or nitriding of steel components. After heat treating, heavy plated copper deposits can be stripped or machined away to provide variable surface hardness across a product.

Heavy Build Plating – Why Advanced Plating Technologies?

The proper application of heavy build deposits is a unique and demanding subset of the metal finishing industry. As in deep-sea diving, issues that are not a problem at common thicknesses can become very severe several orders of magnitude beyond common commercial thicknesses. Issues that can arise when heavy build plating in any finish include:

- Maintaining part dimensional tolerance;

- Maintaining surface finish on critical surfaces;

- Preventing nodulation or pitting of the plated deposit;

- Addressing racking locations and rack marks;

- Adjusting bath parameters and plating rates to yield successful deposits;

- Minimizing deposit stress in tensile stressed deposits;

- Accurately measuring heavy build deposits;

- Masking of features that cannot accept heavy build deposits due to tolerance issues.

Advanced Plating Technologies has an interest in pursuing heavy build deposits beyond what is commonly considered possible. The technical sales and engineering group at APT welcomes the opportunity to discuss your specific heavy build application and design considerations.

You can contact a member of our technical sales group to discuss your specific application. If submitting a request for quote from our website, a text box is provided to detail heavy build plating requirements.