The value of gold as a noble metal has been observed for centuries across a range of decorative, functional, and industrial applications. In an increasingly connected world, the benefits of gold plating are being utilized like never before for high reliability contacts and connectors to ensure rapid and reliable signal transmission. Since 1948, Advanced Plating Technologies (APT) has delivered gold plating services across an array of demanding industries, including the interconnect and medical sectors as well as the Telecommunication and defense industries.

As an ISO 9001:2015 & 13485:2016 certified and ITAR registered company, Advanced Plating Technologies provides gold plating services for even the most demanding applications. APT offers barrel, rack, and vibratory plating of loose-piece components in hard and soft gold as well as duplex gold plating. APT offers 99.9% pure (Type III) soft gold and 99.7% purity hard gold (Type I or II) and can provide a range of underplate combinations to meet nearly any ASTM, Military or OEM specification.

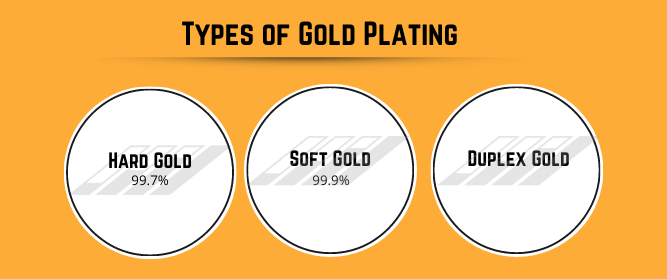

Types of Gold Plating

The primary types of gold plating are commonly referred to as hard gold or soft gold plating with duplex gold being a combination of both. A brief description of these three major types of gold plating services is provided below:

- Hard gold plating – in hard gold plating a small percentage of an alloying element or compound are added to improve the hardness and wear properties of the gold deposit. Commonly cobalt or nickel are used but iron and even arsenic have been utilized as well. Hard gold deposits have a refined grain structure that produces a brighter overall gold appearance. The increased hardness of hard gold plating benefits applications where there is repeated engagement or sliding contact.

- Soft gold plating – unlike hard gold plating, soft gold is virtually pure gold with purities of 99.9% or more. The grain structure of soft gold is less refined than hard gold which makes the deposit have a maximum hardness of 90 Knoop. Due to the high purity, soft gold is excellent for wire bonding or high temperature applications since there are no alloying elements to oxidize.Soft gold is also ideal for low-load, static contact designs such as lapping connections. Soft gold is often preferred for medical applications due to the high purity and biocompatibility of the finish.

- Duplex Gold Plating – In duplex gold plating, both hard and soft gold deposits are deposited to engineer a finish that had properties of both gold plating types. For example, a highly corrosion resistant layer of soft gold can be top coated with a deposit of hard gold to improve the wear properties of the overall gold plating.Duplex gold deposits also have less overall deposit porosity due to the mismatching grain structures between the two gold layers. This can provide enhanced corrosion resistance at a lower overall gold consumption as compared to single-layer gold deposits.

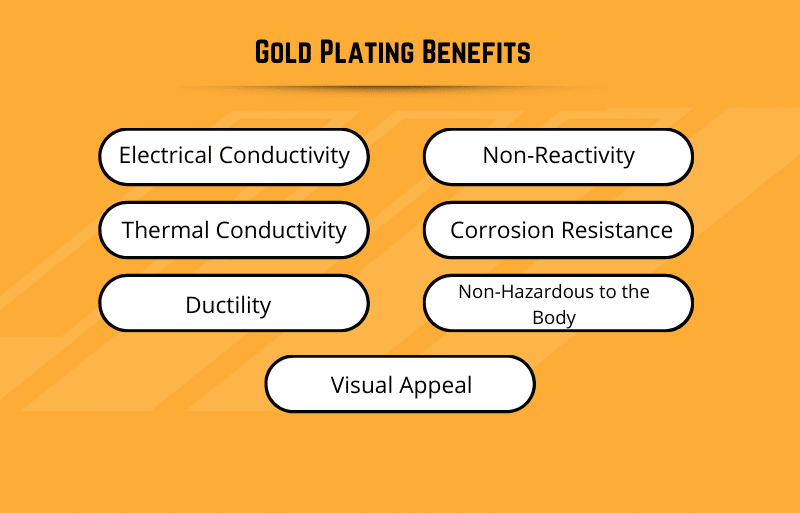

Gold Plating Benefits

The various benefits afforded by gold electroplating include:

· Thermal Conductivity – Similarly to electrical conductivity, gold is the third most thermally conductive metal at 315 W/m*K, second once again to silver and copper. Since it does not form insulating compounds on the surface, its high thermal conductivity is retained even in extreme applications such as down-hole drilling or applications in outer space.

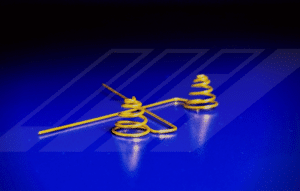

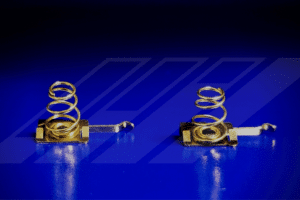

· Ductility – Gold is an extremely ductile metal making it ideal for flexible contacts or springs. The ductility of gold helps ensure that the benefits of the gold will survive repeated contact cycles. It is important to note that proper underplate selection and application are critical to ensure the entire finish will meet design requirements for your gold plated electrical contacts or springs.

· Non-Reactivity – Gold is a noble metal meaning that it does not react or form compounds with other elements it contacts. It is this property that enables nuggets of pure gold to be found in nature even after millions of years of exposure. This unique property of gold is what makes gold plating an excellent barrier coating to promote corrosion resistance.

· Non-Hazardous to the Body – Gold plated medical devices may be safely placed within the human body without concern for biocompatibility. Gold possesses a natural resistance to germs and bacteria and withstands autoclave cycles extremely well making it ideal for orthopedic tools and devices. In addition, gold is radiopaque making gold plating an ideal coating for marker bands or other arthroscopic instruments.

· Visual Appeal – Gold electroplating improves the appearance of items with a finish that does not readily tarnish or oxidize provided the deposit thickness is sufficient. The intrinsic value of gold is universally recognized and denotes a quality product no matter the application.

Conclusion

It is important to note that the many benefits of gold plating must be coupled with a properly engineered finish. Thickness and type are important considerations; however, the underplates that are deposited prior to the gold topcoat are just as critical to the overall success of the finish.

In addition, the proper pretreatment and activation of the base metal are critical to ensure the final gold deposit will perform to the highest level. APT’s technical sales and engineering team can help provide design guidance as well as develop a test plan for any component or application.

For more information on gold plating and other metal finishing services we offer, give us a call today at 414.271.8138 or end us a message through our contact form, or request a quote links.