Selective Plating Services (Electroplating and Electroless Plating)

APT offers a wide range of masks and masking techniques to meet the requirements of most selective plating applications. Custom die-cut tapes and silicon sheet, custom-molded silicon masks, various application-specific tapes, standard silicon masks, and mating parts are just some examples of the masks used.

The tolerances of a selective plating application dictate the type of mask and method of masking application. Custom fixtures can be engineered as part of the masking development to ensure consistent placement within tight tolerances for critical applications.

Selective Plating (Electroplating) – Why Selective Plating?

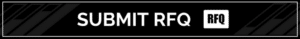

- Bearings or Bushings: Selective plating is often utilized to eliminate plating build on surfaces where the plated babbitt is not desirable. In addition, bearing plating applications commonly have very tight tolerance requirements such as wall thickness and concentricity that are difficult to meet if both the ID and OD of the bearing are plated. By selective plating of only the functional surfaces, tighter overall part tolerance can be achieved.

- Soldering, Welding or Brazing Applications: In certain applications in joining, the plated deposit is undesirable on a feature where the product is to be joined. An example would be where a product is gold plated on one end for soldering but needs to be welded on an opposing end where gold inclusion within the weld joint is undesirable.

- Precious Metal Applications: As precious metals continue to increase in cost, the cost benefit of selective plating only the functional surfaces where gold or silver is required becomes stronger. The cost of the labor in selectively plating loose-piece components needs to be carefully weighed against the material savings. Applications such as contacts received on a carrier or fret are the classic application were selective plating of the carrier strip can yield significant material savings with a minimal increase in labor.

- Complex Geometries: Complex part geometries such as manifolds often require selective plating services utilizing masking to prevent air entrapment within the part and resulting inadherant immersion deposits.

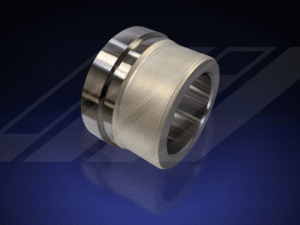

- Heavy Build Applications: External threads or interference fits are often masked in heavier deposit applications to prevent oversize of the outside, inside or pitch diameters.

- Blind Holes: Often blind holes are masked in critical applications to prevent the potential for entrapment of plating chemistry resulting in workout staining of aesthetic concerns.

Assemblies: Selective plating services of assemblies can be required to prevent deposition on components of the assembly where the coating is undesirable from a functional standpoint. Masking can also be provided to protect dissimilar metals of an assembly from the chemistry of the plating process.

You can contact a member of our technical sales group to discuss your specific application. If submitting a request for quote from our website, a text field is provided to detail any specific selective plating requirements.