Silver Plating of Stainless Steel – Silver Properties

Silver plating on stainless steel and other high temperature alloys such as Inconel®, Nitronic® and Hastelloy® is a common silver plating service for nuts, fasteners, slip-rings, thrust-washers, bushings and other bearing surfaces that benefit from the lubricity of silver at high temperatures allowing parts to exhibit anti-galling and anti-seizing properties. Silver is a unique precious metal that exhibits many desirable properties for utilization across a broad range of engineered applications. Of all metals, silver has the highest thermal conductivity, electrical conductivity, and optical reflectivity in the visible portion of the electromagnetic spectrum; silver has outstanding temperature resistance with a melting point of 962° C (1763° F). Additionally, silver is a soft, ductile metal with good embeddability that performs well under high torque and loads. Silver also provides excellent solderability and brazing characteristics for joining applications of stainless steel and other high temperature alloys. The unique combination of lubricity, high temperature resistance and thermal conductivity make silver plating on stainless steel and other high temperature alloys an outstanding combination for high temperature fastening or bearing applications where heat transfer high temperature lubricity are the principle design considerations.

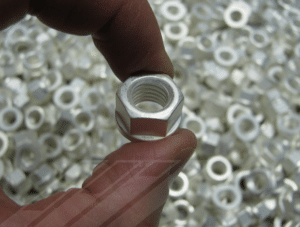

Stainless steel as a base material is beneficial in many industrial applications because of its resistance to corrosion and high tensile strength. Stainless steel has these properties due to its chromium and nickel content which forms a passive oxide layer when exposed to oxygen; protecting the metal from corrosion due to water and air exposure. Under low oxygen conditions, this protective effect cannot be fully realized since the lack of oxygen prevents the oxide layer from forming. When stainless steel parts are forced together and subjected to high temperatures, this passive oxide layer can be scraped away, causing destructive galling of the parts. Galling of stainless steel can result in the threads of nuts and bolts to seize and break away under forced disassembly. Silver plating on stainless steel is a solution to protecting parts in low oxygen environments and preventing the galling of nuts, fasteners, gears, and bearing surfaces at high temperatures.

Process Considerations

The unique properties of stainless steel and other corrosion resistant alloys such as Inconel®, Nitronic® and Hastelloy® make these metals much more challenging materials to plate than other more mild alloys. Stainless steels and other high temp alloys commonly have higher concentrations of corrosion resistant elements including chromium, nickel and cobalt. These elements form tenacious, passive oxide films on the surface that must be removed to create an active stainless steel surface that can be silver plated. Commonly a low metal, high acid nickel strike layer such as a Woods nickel strike is employed to activate stainless steel prior to silver plating. Advanced Plating Technologies has developed a modified, high-performance Woods nickel process that is effective in activating all stainless steel and high temperature alloys including stainless steel, Inconel®, Nitronic® and Hastelloy®. This process has the ability of removing the tenacious oxides layers while simultaneously depositing a thin, active nickel layer. Subsequent to the nickel strike, a low metal concentration silver plating bath is used to deposit a thin, adherent silver strike on the stainless steel that can then be plated upon with the final silver layer. One of the key techniques when plating the silver strike layer is to ensure that the plated parts enter the silver strike in an electrically energized or “live” state to prevent inadherant immersion silver deposition from occurring.

Silver plating can be deposited in either matte, semi-bright, or bright deposits. For most industrial applications, matte or semi-bright plating is utilized because the higher purity of silver offers superior performance over that of fully brightened silver finishes with organic additives. Silver plating of loose piece parts can be accomplished by either barrel or rack plating. Smaller parts such as nuts, bolts, and other fasteners are good candidates for barrel processing which due to the mass loading, unloading and processing of a plating barrel offers considerable cost advantages. Larger parts, typically 3 inches in length or greater than 0.100 pounds, are typically rack processed to prevent any physical damage to the parts during the tumbling that occurs in barrel processing.

Specifications

Most silver plating specifications including ASTM B700, QQ-S-365 and AMS 2410 are applicable to silver plating of stainless steel. However, AMS 2411 is a silver plating specification specific to high temperature applications such as plating on stainless steel lock nuts and fasteners. The basic process steps are outlined as a nickel strike, silver strike and silver plate consistent with the process steps noted above. However, within AMS 2411 special consideration is given to eliminate the use of any organic based grain refining and brightener additives within the silver strike and silver plate layers. Only high purity 99.9% silver is specified to reduce adverse effects that reduced purity can have on the high temperature function of the silver deposit. Alloying metals other than silver and any organics that may codeposit from the use of grain refiners or brighteners can oxidize and even burn (char) resulting in reduced function of failure of the silver at elevated temperatures. As such, APT recommends the use of high purity 99.9%, matte silver for plating of stainless steel or other high temperature alloys including Inconel®, Nitronic® and Hastelloy®.

Corrosion Resistance and Silver Sulfide

Stainless steel is corrosion resistant in many environments, however, can be attacked in more highly corrosive environments, specifically those with high chlorides including marine, chemical processing and oil and gas environments. Silver plating offers outstanding barrier protection from corrosion especially in aggressive chemical environments including high-chloride atmospheres. Silver, being a precious metal, does not oxidize under normal conditions but rather reacts with atmospheric sulfur to form silver sulfide. Silver sulfide, or silver tarnish, is unique from typical metal oxide compounds in that it is a conductive compound that does not significantly degrade from the conductivity or solderability of the silver. In addition, various supplemental anti-tarnish treatments are available for silver plated parts which can slow tarnishing by sealing the surface from exposure to air and water. Advanced Plating Technologies also offers engineered packaging solutions for silver plated components including the use of specific vapor corrosion inhibiting (VCI) packaging materials as well as packaging in heat-sealed bags filled with pure nitrogen. This type of packaging will fully eliminate the chance of silver tarnish over extended storage.

Summary

The use of silver plating on stainless steel and other corrosion resistant alloys including Inconel®, Nitronic® and Hastelloy® offers many surface engineering benefits. Silver plating imparts outstanding lubricity, anti-galling and corrosion resistance benefits even at high temperatures and heavy loads. Only high purity silver should be used in high temperature service to avoid the oxidation or charring of inorganic or organic alloying constituents within the silver deposit.

The above information is provided as a general guide when specifying silver plating on stainless steel or other alloys. There are many other considerations to evaluate when specifying silver plating or other materials for use in a specific application. Advanced Plating Technologies offers extensive surface engineering support for silver plating or other applications. Reverse engineering of existing or failed applications is available as part of services.

Have Questions? Contact us at [email protected]

Blog Authored by: K. LoGiudice, Estimating & Process Engineer