Coatings for the Electric Vehicle Market

Advanced Plating Technologies 70+ year background in conductive finishes within various electrical industries including the power transmission & distribution and electronics industries that have set the history/experience for the EV market. From copper underplates to final finishes, Advanced Plating is able to help provide conductive finishes to most electric vehicle components. With a dedicated Engineering and Technical Sales staff APT has the know-how to help provide plating solutions and design support for any EV project.

Finish Capabilities for Electric Vehicle Components

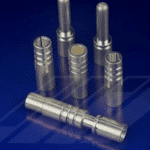

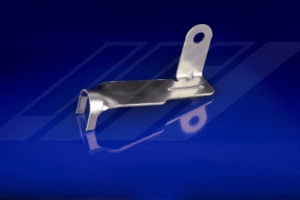

Plating on various copper & copper alloys, aluminum and stainless steel base materials. APT provides Rack, Barrel and Vibratory plating for Electric Vehicle components such as Busbars, Terminals, Pins and more. APT is able to adhere to most company specifications.

Core capabilities in plating of conductive finishes needed within the Electric Vehicle market including

Silver: Silver plays a critical role in EV. Due to the demand for a coating that can pass high current and be exposed to high temps, Silver plating is Vital to the EV market and is a great coating for ultrasonic welding applications. Advanced Plating can provide Silver Plating of EV Components to most company specifications.

Electroless nickel: Have Adhesion issues or concerns? APT’s Electroless Nickel provides as a great underplate to help with adhesion. Electroless Nickel is also used to help provide corrosion & erosion protection. Advanced Plating offers both Medium Phosphorus & High Phos options for EV Components.

Nickel: APT provides functional electrolytic nickel for welding & brazing of conductors and terminals for electric

Tin: Where soldering is required or low conductivity APT’s Matte Tin Plating is a great option since it is Free of brightners. APT’s Bright Tin plating is also a good fit for any EV components such as bus bars that don’t require any soldering or welding and are in need of selective tin plating. APT offers both bright and matte tin for most company specifications.

Powder Coating: Epoxy powder coating is an efficient and cost effective alternative for coating busbars. Epoxy powder coating bonds directly to the copper, aluminum or silver plated busbar, has a higher operating temperature then plastics and can be used on odd shaped parts and busbars. APT has the ability to provide both turnkey powder coating and plating helping alleviate supply chains.

Engineering design support for developing a finish specific to an Electric Vehicle Application

APT provides Technical Engineering Support for Electric Vehicle projects that require plating. Have an existing project that you are experiencing adhesion or corrosion issues on? APT provides design support and product development with existing applications. With 70+ year experience with conductive coatings, there is no job to difficult. Have a new project that you are in need of Specification recommendations for? APT is happy to provide support when writing a specification for your new project.

A Few examples of application support:

- Ultrasonic Welding

- Brazing

- Corrosion resistance

- Switching & contact cycle life

- Thermal cycling

Electric Vehicle Plating Solutions

Welcome to Advanced Plating Tech, your trusted provider of high-quality plating solutions for the electric vehicle (EV) industry. With our extensive experience and cutting-edge technology, we offer a wide range of plating services tailored specifically for electric vehicles. From functional components to decorative finishes, we have the expertise to meet the unique requirements of the EV industry.

Why Choose Advanced Plating Tech for Electric Vehicle Plating?

- Industry Expertise: With years of experience in the plating industry, we have developed a deep understanding of the unique needs and challenges of the electric vehicle sector. Our team of skilled professionals is well-versed in the latest advancements and industry standards, ensuring superior plating results for EV components.

- Comprehensive Plating Solutions: At Advanced Plating Tech, we provide a comprehensive range of plating services for electric vehicles. Whether you require corrosion-resistant plating for battery terminals or conductive plating for electrical connectors we have the capabilities to meet your specific needs.

- Advanced Plating Techniques: We employ state-of-the-art plating techniques to ensure precision and durability. Our advanced processes, including electroplating, electroless plating, and selective plating, guarantee consistent and reliable results for even the most complex EV components.

- Customized Solutions: We understand that each electric vehicle project has unique plating requirements. Our team works closely with you to develop customized plating solutions tailored to your specific needs. We can accommodate various plating specifications, thicknesses, and finishes to achieve the desired functionality and aesthetic appeal for your EV components.

- Quality Assurance: At Advanced Plating Tech, we are committed to delivering the highest quality plating solutions. We adhere to stringent quality control measures throughout the plating process, conducting thorough inspections and tests to ensure that every component meets or exceeds industry standards.

- Sustainability: As an environmentally responsible company, we prioritize sustainable practices in our plating processes. We utilize eco-friendly plating solutions and implement waste reduction strategies to minimize our environmental footprint and contribute to a greener future.

Contact Us for Exceptional Electric Vehicle Plating Services

If you are seeking exceptional plating services for electric vehicles, Advanced Plating Tech is your trusted partner. Contact us today to discuss your specific needs, request a quote, or schedule a consultation. Our dedicated team is ready to provide you with top-quality plating solutions tailored to the unique requirements of the electric vehicle industry. Experience the difference of working with a reliable plating provider that combines expertise, innovation, and a commitment to customer satisfaction.