Selective Powder Coating by Advanced Plating Technologies

Advanced Plating Technologies provides selective powder coating as part of a full family of powder coating services to fulfill even the most demanding engineering applications. Where most powder coating job shops avoid the demands of selective powder coating applications, Advanced Plating Technologies welcomes challenging selective powder paint requirements. Advanced Plating Technologies has refined a wide range of masking techniques and can handle most applications including high cosmetic selective powder coating applications.

Advanced Plating Technologies provides selective powder coating as part of a full family of powder coating services to fulfill even the most demanding engineering applications. Where most powder coating job shops avoid the demands of selective powder coating applications, Advanced Plating Technologies welcomes challenging selective powder paint requirements. Advanced Plating Technologies has refined a wide range of masking techniques and can handle most applications including high cosmetic selective powder coating applications.

Over 80% of all active powder coating jobs at Advanced Plating Technologies require selective powder coating, with most jobs requiring extensive masking application. A wide range of selective powder coating techniques can be provided including rack shielding, mating components or fasteners application, custom die-cut tapes and sheet product, standard silicon masks, and custom molded masks specific to a part geometry.

Selective Powder Coating – Why Selective?

Powder coating is a highly durable painting process that has found diverse application in manufacturing today. One of the key advantages of powder paint is the higher mil-thickness over standard wet apply paints. Although this is an advantage from a corrosion and durability standpoint, it presents considerable fit and function issues of mating components.

The following list summarizes common applications of selective powder coating:

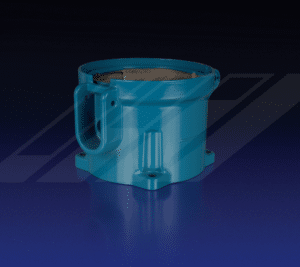

- Sliding Wear: Powder coating, although durable for a paint process, does not have hardness sufficient for most sliding or wear applications. Selective powder coating prevents coating build on critical wear surfaces.

- Part Tolerances and Threaded Features: Powder coating builds an average thickness of 0.001-0.004 inches per side. The magnitude and nonuniformity of powder paint thickness is an inherent coating property. This amount of paint is commonly a concern for threaded surfaces as well as tighter tolerance features. Selective powder coating allows for the benefits of powder paint on most surfaces without fitment issues on these critical dimensional features.

- Sealing Surfaces: Due to the fact that powder paint is an organic coating, it does not work well with sealing of gasket materials on sealing surfaces. To ensure proper function, most gasket or seal surfaces require selective powder coating.

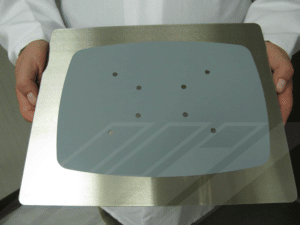

- Conductive Surfaces: Powder coating is a relatively thick organic coating and as such is both an electrical and thermal insulator. Many powder coated components used in the electronics, telecommunications and powder distribution industries must be masked at locations designed to pass current or heat, such as bus bar ends, grounding points, heat sinks or terminal contacts.

Advanced Plating Technologies welcomes the opportunity to provide selective powder coating across a wide range of applications. Our technical sales group can work in association with product design and engineering staff to determine the best methods and techniques to provide the selective powder paint. Advanced Plating Technologies has the capabilities of coupling plating and powder coating finishes for applications in selective powder coating where the masked features must retain conductivity. Common applications include electroless nickel plating, tin plating and silver plating combined with selective powder coating.

You can contact a member of our technical sales group to discuss your specific application. If submitting a request for quote from our website, a text field is provided to detail any specific selective powder coating requirements.