Advanced Plating Technologies, a Milwaukee,

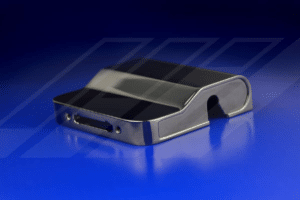

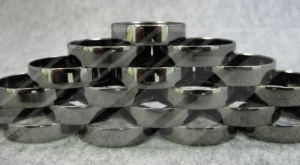

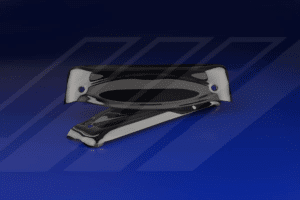

Advanced Plating Technologies can offer your company a wide range of black nickel plating services ranging from bright “jet-black” deposits to satin “charcoal gray” finishes. The characteristics and appearance of APT’s black nickel plating services are a function of the basis material and/or underplating that is plated prior to the black nickel topcoat. Generally speaking, a highly polished substrate with a bright nickel underplate will result in a lustrous, jet-black finish often referred to as a “black chrome” appearance. Conversely, a matte or satin substrate such as a machined, glass-blasted or grained surface coupled with a satin nickel underplate such as electroless nickel will produce a satin charcoal gray appearance. Currently a matte, jet-black appearance is not available.

The corrosion performance of Advanced Plating Technologies’ black nickel plating is primarily a function of the complete finishing system. If a specific corrosion performance is required the surface preparation of the substrate as well as the type, thickness and number of underplates used can be engineered to meet your finishing requirements (reference: What causes metals to oxidize or “rust” in our Plating Topics section). The use of a copper underplate and specifically selected nickel underplates can be provided to meet most corrosion applications.

Black Nickel Plating Capabilities

Black Nickel Plating Services

Specifications:

MIL-P-18317

Most Company Specifications

Finish Type:

Bright Jet Black When Plated Bright Over Smooth Surfaces (Ra < 10uin) Semi-bright Charcoal Grey When Plated Semi-Smooth Surfaces (Ra 16-64uin) Matte Grey When Plated Over Rough Surfaces (Blasted, Ra > 64uin)

Substrates Plated On:

Ferrous: All Ferrous Alloys Including Mild Steel, Stainless Steels, Hardened Steels & Tool Steels

Cuprous: All Cuprous Alloys Including Pure Copper, Copper Alloys Including Tellurium & Beryllium, Brass, Nickel-Silver

Aluminum: All Aluminum Alloys Including Wrought, Cast and Proprietary Alloys (MIC-6)

Exotics: Inconel, Pure Nickel (Nickel 200), Cobalt-Chrome (MP35N), Kovar, Monel, Hastalloy, Monel, Lead

Part Size Limitations: 24 Inches x 30 Inches x 10 Inches

Underplates Provided:

Bright Electrolytic Nickel

Sulfamate Electrolytic Nickel

Electroless Nickel (High or Medium Phosphorous)

Copper

Heat Treatments:

Hydrogen Embrittlement Bakes

Stress Relieving Bakes

High Temperature Bakes up to 750F

Methods:

Barrel

Rack

Wire

Vibratory

Selective Loose Piece Plating

Sheet Product (Chemically Milled/Etched Sheets)

Segmented Strips (Frets)

Sn Ni Specifications

The most common black nickel plating service certified by Advanced Plating Technologies is MIL-P-18317. Our company also can certify black nickel plating services to most company specific black nickel specifications. A summary of the MIL spec is provided below:

Black Nickel Plating to MIL-P-18317

MIL-P-18317 does not provide a Type, Class or Grade callout. A few key points regarding the specification are summarized as follows:

3.3.1. Unless otherwise specified in the contract or order, the black nickel plating shall be applied to the basis metal without intermediate coating after all mechanical operations on the basis metal.

3.3.2 Intermediate Coating: When specified in the contract or order, an intermediate coating such as nickel plating shall be applied to the basis metal for the purpose of improving the corrosion protection.

3.4.1 Color of the Deposit: The deposit shall be a uniform black color which shall conform to the color of the approved sample (as approved by the customer).

6.3 Definition of black nickel plating – this section outlines a common “historic” black nickel formulation. The section permits for any available formulation to be used by stating, “The (above) formula is typical of the thiocyanate baths employed for black nickel plating. Other formulas for black nickel solution producing an equivalent coating may be used.”

Sn Ni Properties

Advanced Plating Technologies’ black nickel plating services are a RoHS compliant codeposit of tin and nickel in a common plated layer. As a result, the black nickel properties are a mix of that of nickel plating and tin plating. The co-deposited tin in the black nickel affords an inherent dry-film lubricity exceeding that of common nickel deposits. The hardness of the black nickel deposit is consistent with traditional electrolytic nickel deposits. However, due to its relatively thin deposit thickness of 1um (0.00004 inches), black nickel topcoats can be susceptible to break through in high wear applications.

Advanced Plating Technologies’ black nickel plating provides a highly conductive surface and has excellent “throw” or ability to plate uniformly on complex geometries. Being a codeposit of tin and nickel, APT’s black nickel services can be directly soldered or brazed to making it an excellent fit for applications within the interconnect or telecommunications markets. Black nickel can be used where high emissivity is required such as optics, solar panel applications, aerospace and defense systems.