Electroless nickel plating offer key benefits over traditional electrolytic plating due to the fact that the electroless deposits are formed without the need of externally applied electrical current. This results in deposits that are free of the edge buildup of dog-bone effect common with electrolytic plating. In addition, the nickel/phosphorous alloy composition provides improved hardness, lubricity and corrosion resistance over that of traditional electrolytic nickels and can be heat treated to modify as-plated properties. Advanced Plating Technologies offers a diversity of standard EN plating services as well as a proprietary Tacti-Black® Electroless Nickel. HP+ (High Performance Plus) variants in both our traditional and black electroless nickels are offered for the highest in corrosion resistance and dry-film lubricity.

Electroless Nickel Plating

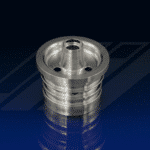

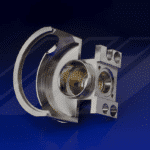

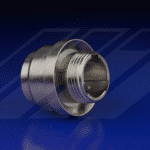

Advanced Plating Technologies provides barrel and rack electroless nickel plating services in medium and high phosphorous to MIL-C-26074, ASTM B733 and AMS 2404 on most metallic substrates. APT currently services an extremely diverse industry base including the medical, power transmission & distribution, oil & gas and defense industries. APT’s proprietary HP+ (High Performance plus) utilizes a molecular sealer bonded to the plated surface to promote the highest corrosion resistance and dry-film lubricity. Post plate baking can be provided without discoloration to attain a micro-hardness of 1000 HV (Rc 69). APT also provides heavy-build EN plating services up to 0.005 inches per side commonly employed within the Oil & Gas and Petrochemical markets to address severe corrosion and erosion application requirements.

Black Electroless Nickel (Tacti-Black®)

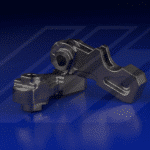

Advanced Plating Technologies provides an industry-leading black electroless nickel plating – Tacti-black® Electroless Nickel – which combines the exceptional lubricity, deposit uniformity, hardness and corrosion resistance of EN with a fully conductive and uniform black appearance. Unlike many black electroless nickels, Tacti-black® Electroless Nickel can be soldered to and can be topcoated with a powder coat paint with excellent paint adhesion. For the deepest black color coupled with the best corrosion resistance and lubricity, APT offers Tacti-Black® HP+ Electroless Nickel which utilizes a molecular sealer to impart improved deposit performance. Tacti-Black® is currently utilized in a wide range of industries including the firearm, defense, interconnect, telecommunications and aerospace industries.

Electroless Nickel Phosphorus Content

Advanced Plating Technologies offers both Type IV medium phosphorous and Type V high phosphorous deposits. Depending on requirements such as hardness, magnetic properties and corrosion protection APT can offer phosphorus contents between 5-9% and 9% or greater with and without a bake. Our engineering group can help specify a specific deposit for your application based upon your specific design considerations.

Tacti-Black® Electroless Nickel Firearm Finishes

Tacti-Black® electroless nickel plating on firearm components offers several improvements over other black finishes available. Greater corrosion resistance, a more consistent black finish regardless of substrate, enhanced lubricity as well as maintaining tight tolerances during the plating process. Tacti-Black® HP+ is unmatched in consistency and lubricity for critical action components including as sears, hammers, triggers, extractors and pins. APT is ITAR registered and holds a type 10 FFL (Federal Firearms License) to handle processing of serialized firearm components.

Electroless Nickel Plating vs Electrolytic Nickel Plating

The electroless nickel plating process (EN) has several distinct advantages over the traditional electrolytic nickel plating process. The primary difference with the nickel plating process is that EN does not require the application of an external electrical current to drive the deposition as does electrolytic nickel. Rather, EN uses a chemical reducing agent within the solution chemistry which results in nearly uniform deposition on all surfaces that are wetted by the EN chemistry. Since the electrolytic nickel plating process requires the application of an externally applied DC current, the deposit tends to be non-uniform with excess deposit on the edges or corners (high current areas) of the part.

A Guide to Electroless Nickel Plating