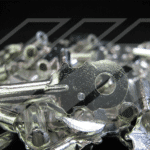

Advanced Plating Technologies offers a diversity of electrolytic plating services in barrel, rack and vibratory “loose piece”methods across a wide range of demanding sectors including the medical, ammunition,defense, power transmission, oil & gas, electronic & interconnect industries. Electrolytic plating is a process which requires an externally applied DC current for deposition to occur as opposed to electroless plating processes in which the deposition occurs from an autocatalytic reaction of the plating chemistry with the base material. The vast majority of plated finishes can only be provided commercially with electrolytic plating. A brief summary of the precious and nonprecious metal electrolytic plating services offer by Advanced Plating Technologies is provided below.

Gold Plating Services

Advanced Plating Technologies, offers gold plating in both 99.7% pure hard gold and 99.9% pure soft gold electrodeposits.Hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration.Soft gold plating is commonly used where the highest of gold purity is required for soldering, wire bonding, high temperature, biocompatibility or high corrosion resistance applications. Gold is a fully noble or non-reactive metal that does not form oxides or compounds. This unique “precious” property makes gold an outstanding choice for critical electronic and interconnect applications where the highest reliability bonding, conductivity and signal transmission are principle design considerations.

Silver Plating Services

APT offers a wide range of silver plating services including matte, semi-bright and bright silver deposits. Deposit purity of up to 99.9% is available for applications that demand the highest conductivity or high temperature lubricity. Silver plating has excellent anti-galling, thermal and electrical conductivity properties as well as outstanding solderability. Silver is not a truly precious metal in that it can form sulfur compounds commonly referred to as tarnish. However, these sulfur compounds are very conductive and do not significantly degrade the performance of the silver unlike other metal oxides. In addition, APT offers various “Tarniban” anti-tarnish inhibits and can custom engineer inert packaging solutions such as sealed pure nitrogen packaging to avoid silver tarnishing in storage.

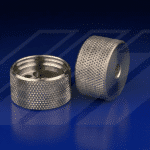

Nickel Plating Services (Electrolytic)

Advanced Plating Technologies offers a wide range of traditional electrolytic nickel plating services including both Type I “unbrightened” and Type 2 “brightened” deposits. Nickel is commonly used for conductive applications and provides excellent corrosion and wear resistance. Nickel is often plated as a diffusion barrier prior to a tin, silver or gold final layer to prevent solid state diffusion or intermetallic growth between the base material and final topcoat. Type I brightened nickel deposits have the ability of leveling the surface as they plate producing an appealing, lustrous finish that enhances the appearance of products. For functional applications that require bonding, brazing, soldering or crimping, APT only recommends the use of unbrightened Type 2 sulfamate nickel plating services. For applications that require crimping with a lustrous finish, APT offers a proprietary Ducta-bright 7a® nickel process far superior to traditional brittle electrolytic bright nickel processes.

Sulfamate Nickel Plating Services

Sulfamate nickel is a specific type of electrolytic plating that is formulated from a nickel sulfamate rather than the traditional “Watts” nickel sulfate formulation. Sulfamate nickel plating produces a semi-bright nickel deposit that excels in engineered and functional applications. Sulfamate nickel plating produces a high purity, low-stress nickel deposit that performs the best of all nickel deposits (electrolytic or electroless) in flexing or crimping applications as well as in joining functions such as soldering, brazing, epoxy bonding or welding. APT recommends sulfamate nickel as an underplate to gold, silver or tin in most applications that require any type of bonding or flexing.

Black Nickel Plating Services

Advanced Plating Technologies’ black nickel plating has excellent “throw” or ability to plate uniformly on complex geometries in either rack or barrel processing. Commonly black nickel is preceded by a nickel underplate which will impact the final appearance of the black nickelfrom a bright jet black appearance to a satin charcoal gray finish. Being a codeposit of tin and nickel, APT’s black nickel is fully conductive and can be directly soldered or brazed to.

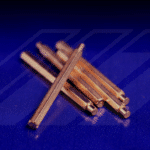

Copper Plating Services

Advanced Plating Technologies offers both alkaline cyanide copper as well as high-speed acid non-cyanide copper plating services. Copper plating is commonly used as an underplate to enhance the conductivity and corrosion resistance of a final deposit. Cyanide copper plating is often used as a strike to improve the bond or adhesion of subsequent plating processes. Copper plating is also used as a metallic lubricant for anti-galling applications as well as for heat treat stop-off for carburizing or nitriding applications. For ammunition applications, APT offers heavy build copper plating of projectiles and components made from lead, powdered metal and armor-piercing materials.

Tin Plating Services

Tin is a soft, ductile, silvery-white metal that is not easily oxidized in air. It has good conductivity and corrosion resistance while enhancing solderability of substrates that are not otherwise easily soldered to. Tin plating is broken up into two primary categories: bright tin and matte (solderable) tin plating. Bright tin plating has a high degree of luster and is generally preferred for electrical contact applications. For solderable applications matte tin is recommended since the deposit is free of the codeposited brighteners found in bright tin plating that can interfere with soldering and uniform wetting.

Tin/Lead Plating Services

Tin/lead plating services are utilized for unsurpassed solderability and in critical electrical and electronic applications to eliminate the potential for tin whisker formation.In addition, tin/lead plating is commonly used for bearing and bushing electrolytic plating applications due to the lubricity and embedability of the soft alloy deposit. Advanced Plating Technologies offers a diverse portfolio of tin/lead plating services including 10/90, 90/10, 60/40, 95/5 and 5/95 formulations. In addition, any custom tin/lead formulation can be produced upon request to meet any company specification for electrolytic plating.

Lead Plating Services

Lead plating services are often employed for highly corrosive applications due to the outstanding performance of lead in corrosive environments, especially when dealing with strong mineral acids such as sulfuric acid in lead-acid batteries. Lead has excellent anti-galling characteristics and is a very soft deposit, making it an excellent babbitt material for bearing and bushing applications.

Black-TPD® Plating

Black-TPD® is a proprietary coating engineered specifically for the premium self-defense ammunition market. Black-TPD® couples the unmatched deposit durability, reloading capacity and ductility of APT’s Ducta-bright 7a® Nickel with a proprietary Black-TPD® alloy topcoat. The result is a duplex coating system with unsurpassed corrosion resistance, dry film lubricity with a premium, liquid-black appearance.

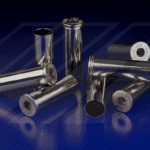

Copper Plating of Bullets and Projectiles

Advanced Plating Technologies provides heavy-build copper plating of lead, steel, tungsten or aluminum cores/projectiles as well as frangible powdered metal cores for tactical or training applications. APT pioneered the use of proprietary high-speed copper chemistries paired with ultra-efficient Spray-Thru™ barrels to provide heavy build copper plating of bullets and projectiles to thicknesses exceeding 0.020-inches per side. APT can provide either plate-to-gauge (size) or plate-to-weight (grain weight) to meet the specific needs of the projectile design.

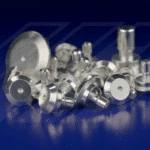

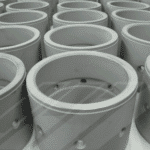

Ducta-Bright 7a® Nickel Plating of Shell Casings

Ducta-Bright 7a® Nickel the superior, ductile nickel plating process for plating of components that must be sized, crimped or otherwise formed post plate. Ducta-bright 7a® Nickel was developed by APT in 2009 to meet the specific needs of the self-defense and law enforcement ammunition market. Today it is the top choice of industry-leading ballisticians for critical self-defense, law enforcement and defense ammunition components. Ducta-bright 7a® Nickel will not crack, flake or peel when sizing, canneluring, loading or reloading. Nickel plating of shell casings with Ducta-bright 7a® provides several key benefits including improved feeding in all actions of firearms, enhanced corrosion resistance, visibility in low-light chamber checks and ease of cleanup during reloading.

Eclipse-TPD® Plating

Eclipse-TPD® produces a smoke-black, matte appearance that is ideal for use where low light reflectivity is a tactical requirement. Eclipse-TPD® utilizes duplex coating technology coupled with a proprietary molecular sealer to provide the highest corrosion performance and lubricity of any ammunition coating available today. Eclipse-TPD® is the result of fifteen years of ammunition coating engineering and is the most advanced component coating available in the ammunition industry today.