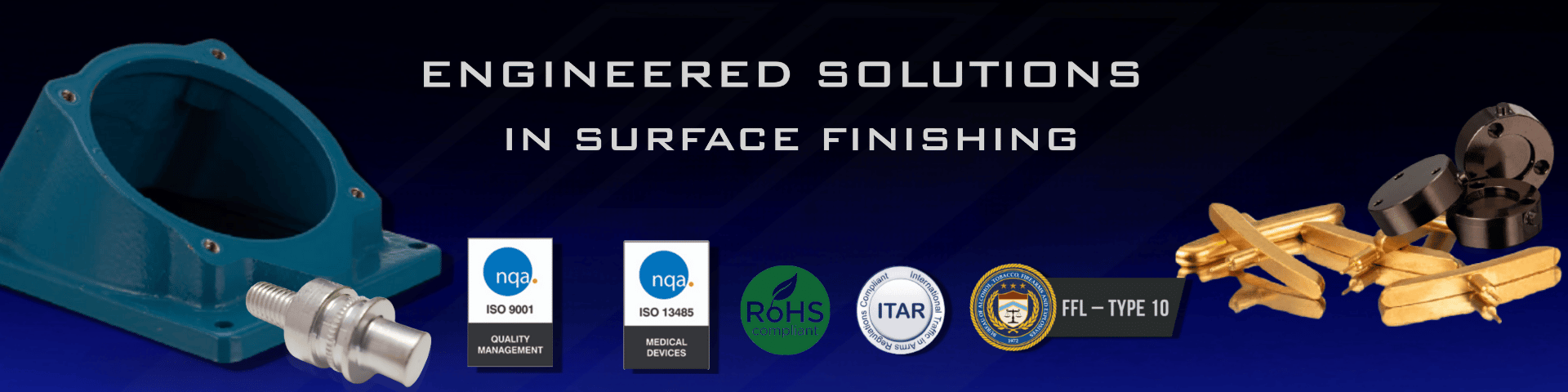

Founded in 1948, Advanced Plating Technologies (APT) is a metal finishing job shop specializing in functional and conductive coatings used within a range of technical industries including the medical, defense, electric vehicle, power transmission/distribution and electronic industries.

What Sets APT apart?

APT’s approach to metal finishing is unique as we are a full-service surface engineering resource to our customers. Value-Added services we offer include:

Surface Engineering Support

Surface Engineering Support

New product design and reverse engineering support to optimize coatings for:

- Soldering, Wire Bonding & Brazing

- Ultrasonic Welding (USW), Laser & Resistance Welding

- Corrosion & Wear Resistance

- Electrical Contact Cycle Life

Engineering Design/Build Services

Engineering Design/Build Services

In-house engineering department provides:

- 3D Printing & Part Modeling Capabilities

- Rapid Prototype Plating Fixtures in 2-3 Days

- Part-Specific Customized Production Fixtures

- Custom Masks for Selective Plating

Quality Deeper than the Surface

Quality Deeper than the Surface

Full quality engineering services for including:

- PPAP, PFMEA & Full Validations (IQ, OQ & PQ)

- Plating Profiling & Process Capability Analysis (CPK & PPK)

- Salt Spray Testing, Cross Section, EDX & SEM Analysis

Exceptional Customer Services

Exceptional Customer Services

A dedicated customer service team provides full-service support including:

- APT Trucking within Regional Area

- Order/Price Confirmations

- Open Order Reports

- Expedite & Partial Shipments