Powder Coating Services – Milwaukee, Wisconsin

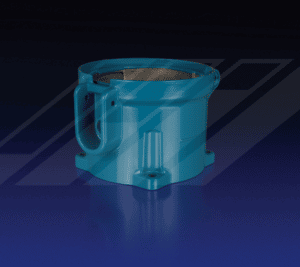

Advanced Plating Technologies provides industrial powder coating services in Milwaukee, Wisconsin including selective powder coating and demanding cosmetic powder coating applications. Advanced Plating Technologies was one of the pioneering companies to offer powder coating services in Milwaukee, Wisconsin when the original powder coating system was installed in 1982. Today, Advanced Plating Technologies a premier provider of industrial powder coating services offering a diversity of resin systems, textures and colors. In addition, APT can simplify your supply chain offering both powder coating and plating services and can provide powder coat paint over a wide range of plated finishes including electroless nickel plating, tin plating and silver plating. APT specializes in powder coating of small to mid-size parts including those with highly aesthetic, selective powder paint or functional performance requirements. Advanced Plating Technologies offers industrial powder coating services within various industries including the medical, defense, marine, power distribution, agricultural and food processing industries.

Advanced Plating Technologies offers industrial powder coating services with nearly all thermoset resin systems including epoxy, polyester, urethane or hybrid paint systems. Multi-layer powder coating systems can be provided including zinc-rich primers prior to final topcoats. In addition, APT provides powder coating with difficult to spray powder paints including metallics, clear coatings and transparent paints. Specific cure cycles of each powder can be monitored and certified using a DATA PAQ temperature profiling system. The exact color of the cured paint is verified against approved standards within our quality control lab using a spectrophotometer to quantify the color in the CIE L*a*b* colorspace. The company offers powder coating services in a wide range of stock colors or custom-match powder can be developed through our rapid prototyping department. Advanced Advanced Plating Technologies provides powder coating services with powder paint from all major suppliers including Akzo Nobel (previously Rohm & Haas), Axalta (previously DuPont), Trimite, TCI, Sherwin Williams and Tiger Drylac to name a few.

Powder Coating Services – Application and Properties

One of the advantages of powder coating services over traditional wet spray paint systems is that the paint is applied as a dry powder which allows for much higher coating thicknesses. In addition, since powder coating is a dry process it does not utilize any liquid solvents for application, resulting in zero volatile organic emissions. During application the powder paint is fed via compressed air through an application system. The spray gun in the system applies an electrostatic charge to the powder particles as they exit the spray nozzle. The charged powder particles are attracted to the grounded workpiece where they are deposited. Since they are applied dry, a much higher thickness can be applied without the common drips or sags of wet spray paints.

The coated parts are then transferred to an oven where the dry powder cures and transitions from a dry state to a liquid state to a fully cured solid state. During the curing process the liquefied paint reacts and cross links to form long-chain polymer molecules that are very resistant to breakdown and chemical attack. The specific cure cycle of the powder coat paint depends on the powder used but generally takes between fifteen to thirty minutes. Typical powder coating cure temperatures range from 275F for low-cure powders to as high as 450F.

Powder coating services have several advantages over traditional wet spray painting as follows:

- Powder coating can produce much thicker coatings without drips, runs or sags compared to conventional wet-spray paint. Typical single-layer powder coating thickness ranges from 0.002 to 0.004 inches. Double coat applications can achieve thicknesses as high as 0.010 inches. Greater mil thickness coatings equate to better corrosion and wear performance.

- Baked powder coatings are generally tougher and more resilient to impact than traditional wet spray paints.

- Powder coating is a green process that does not use volatile organic compounds for application. Powder coating produces virtually no hazardous waste.

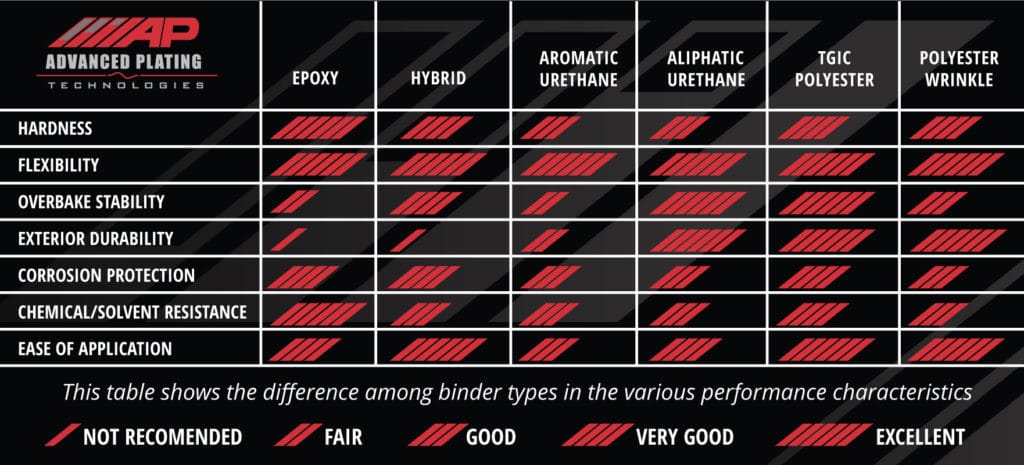

The properties of industrial powder coating services are a primary function of the specific paint resin selected. For example, epoxy resin systems have the highest hardness and chemical resistance but should not be selected for exterior applications where UV stability is a concern. The resin chart below provides a qualitative comparison between properties and performance of the various common powder resin systems. Advanced Plating Technologies engineering group can provide full technical support ton ensure proper selection of a undercoat, primer and final resin system to engineer a powder coating system specific to your application.

Powder Coating Services – Paint Cure and Color Control

In order for powder coating services to perform as the manufacturer intended, the paint must be properly cured based upon the cure cycle recommended by the powder manufacturer. Powder coat paint is applied in a powder state and transitions to a liquid and finally to a cured solid based upon the thermal cycle that the product is exposed to during baking. If the powder sees either insufficient temperature/time or excessive temperature/time in the oven – its corrosion performance, mechanical and cosmetic properties will be compromised.

The mass and material of the product being powder coated greatly affects the specific cure cycle. For example, a large, massive iron casting will require a longer dwell time as compared to a thin aluminum stamping to achieve an equivalent cure. This is because large products with significant mass will have a longer thermal lag to come to temperature within the oven. What matters in curing paint is the temperature of the part surface, not just the temperature of the oven. A proper cure cycle is critical to providing quality powder coating services and consistent processing from lot to lot.

Advanced Plating Technologies develops a quantified thermal profile and powder cure cycle for each part processed as part of the product qualification. To develop this thermal profile a Datapaq temperature logger is run with each product where various thermocouples are placed on the actual product being coated and the temperature/time profile is logged electronically. This data is then recorded with cure cycle analysis software to provide a final cure value of the powder. Datapaq is the leading supplier of cure software for the industrial coatings market and Advanced Plating Technologies has utilized their technology since its advent in the early 1980s.

Powder Coating Services – Advanced Plating Technologies Capabilities

Specifications: Certify to Most Company Specifications

APT Unique Capabilities:

Highly Cosmetic Powder Coating

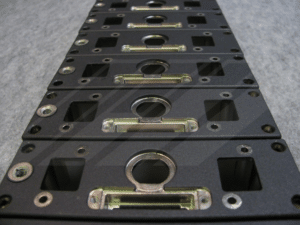

Demanding Selective Powder Coating Applications

Powder Coating Over Plated Finishes (e.g. Powder Over Silver, Tin, Electroless Nickel or Black Electroless Nickel)

Clear Coats or Clear Coats Over Metallics/Pigmented Powders

Resin Types:

Epoxy

Hybrid

Aromatic Urethane

Aliphatic Urethane

TGIC Polyester

Paint Types:

Smooth, Wrinkle & Textured Finishes

Metallic Paints

Clear Paints

Transparent Paints (Translucents or Jolly Pop)

Numerous Stock Colors Offered

Stocking of Any Manufacturer’s Paint

Custom Colors Matched to Pantone Color or Color Chip

Suppliers:

Axalta (DuPont)

Akzo Nobel (Rohm & Haas)

Trimite

Sherwin Williams

TCI

PPG

Cardinal

Tiger Drylac

Most Other Powder Suppliers

Substrates Painted On:

Ferrous: All Ferrous Alloys Including Mild Steel, Stainless Steels, Hardened Steels & Tool Steels

Zinc: Wrought or Cast Grades

Cuprous: All Cuprous Alloys Including Pure Copper, Copper Alloys Including Tellurium & Beryllium, Brass, Nickel-Silver

Aluminum: All Aluminum Alloys Including Wrought, Cast and Proprietary Alloys (MIC-6)

Exotics: Inconel, Pure Nickel (Nickel 200), Cobalt-Chrome (MP35N), Kovar, Monel, Hastalloy, Monel, Lead

Part Size Limitations:

Up to 45 lbs

30 Inches x 36 Inches x 12 Inches

Pretreatment Options:

Vapor Degreasing

Iron or zinc phosphate of steel products

Passivation of Stainless Steel

Chromate Conversion Coating of Aluminum

Polishing or Graining

Sandblasting

Cure Temperatures:

Low Cure Powders Available to 275F

Standard Cures Between 325-400F

Methods:

Rack

Selective Powder Coating

Our industrial powder coating services are for commercial, high volume applications. At this time we do not offer powder coating on custom applications such as personal motorcycles, personal automotive parts, etc.. Please visit Optimum Coating for these services.