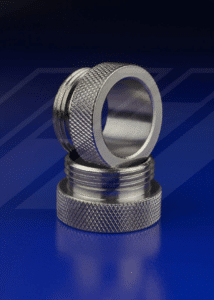

Advanced Plating Technologies, a Milwaukee, Wisconsin company, provides functional and engineered nickel plating services to QQ-N-290, ASTM B689 and AMS 2403 including both Watts and Sulfamate nickel bath formulations. APT’s expertise in providing exacting barrel, rack and vibratory nickel electroplating services is currently employed in numerous industries including the medical, telecommunications, power distribution, petrochemical and electronics industries.

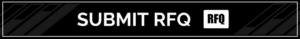

Advanced Plating Technologies can offer your company a wide range of nickel-plating services including both Type I “dull” and Type 2 “brightened” deposits. APT has the ability to underplate with copper plating if required or specified to enhance adhesion and corrosion resistance of the final deposit. For applications that demand the highest in ductility, our company offers a proprietary process called Ducta-bright 7a nickel. This nickel system was developed by APT’s engineering group specifically for application within the ammunition industry. It is unmatched in ductility and adhesion for demanding applications that require a nickel deposit that can be staked, bent or formed post-plate.

Nickel Plating Services – Nickel Deposit Properties

Nickel is a silvery-white metal with a slight golden or yellow hue. As-deposited electrolytic nickel can have a very bright reflective shine, a satin appearance, or a full-dull matte luster. Nickel is one of the four ferromagnetic materials at room temperature and is a fairly reactive element. However, nickel deposits are slow to react in standard atmospheric environments due to the formation of a protective, oxide surface, providing excellent corrosion performance on most products. Nickel has an extremely high melting point of 1455C (2651F) making it an excellent nickel coating for high-temp applications.

For joining applications involving soldering, brazing or laser welding, sulfamate nickel plating is recommended. Sulfamate nickel produces a highly pure nickel deposit free of organic additives, resulting in a 99.9% pure nickel deposit with a satin to dull appearance. Unlike traditional brightened watts nickel systems, sulfamate nickel produces a compressively stressed deposit making is an excellent choice for crimping or flexing applications and as an underplate to gold plating applications including lead frames and interconnect pins.

Nickel Plating Services – Advanced Plating Technologies’ Capabilities

Specifications:

QQ-N-290, Class 1 & 2

ASTM B689

AMS 2403

ISO 1458

Most Company Specifications

Finish Type:

Bright Nickel

Semi-Bright (Satin)

Dull or Matte

Sulfamate Nickel

Watts Bright and Unbrightened Nickel

Woods Nickel Strike

Substrates Plated On:

Ferrous: All Ferrous Alloys Including Mild Steel, Stainless Steels, Hardened Steels & Tool Steels

Cuprous: All Cuprous Alloys Including Pure Copper, Copper Alloys Including Tellurium & Beryllium, Brass, Nickel-Silver

Aluminum: All Aluminum Alloys Including Wrought, Cast and Proprietary Alloys (MIC-6)

Exotics: Inconel, Pure Nickel (Nickel 200), Cobalt-Chrome (MP35N), Kovar, Monel, Hastalloy, Monel, Lead

Part Size Limitations: 32 Inches x 30 Inches x 12 Inches

Underplates Provided:

Copper

Electroless Nickel (Aluminum Alloys)

Heat Treatments:

Hydrogen Embrittlement Bakes

Stress Relieving Bakes

High Temperature Bakes up to 750F

Methods:

Barrel

Rack

Wire

Vibratory

Selective Loose Piece Plating

Sheet Product (Chemically Milled/Etched Sheets)

Segmented Strips (Frets)

Nickel Plating Services – Nickel Plating Specifications

The two most common nickel-plating services certified by Advanced Plating Technologies are QQ-N-290 & ASTM B689. APT can also certify nickel plating services to ISO 1458, AMS 2423 and AMS 2403 well as most company-specific nickel specifications. A summary of the nickel-plating types per the ASTM and MIL specs is as follows:

Nickel Plating Services to QQ-N-290

Class 1 – Corrosion Protective Plating

Class 2 – Engineering PlatingTable 1 Lists the Following Minimum Thicknesses:

Grade A – 0.0016 Min Thickness Plating

Grade B – 0.0012 Min Thickness Plating

Grade C – 0.0010 Min Thickness Plating

Grade D – 0.0008 Min Thickness Plating

Grade E – 0.0006 Min Thickness Plating

Grade F – 0.0004 Min Thickness Plating

Grade G – 0.0002 Min Thickness Plating

QQ-N-290 Class 1 Categories:

SB – Single Layer Bright Nickel Deposits

SD – Single Layer Dull or Semi-Bright (Satin) Deposits

M – Multilayer Nickel Deposits

3.2.5 Underplating: When specified in the contract, purchase order or applicable drawing, Class 1 plating shall be applied over a plating of copper on steels, copper and copper-based alloys. Class 1 plating shall be applied over an underplating of copper or yellow brass on zinc and zinc-based alloys. In no case shall the copper underplate be substituted for any part of the specified nickel thickness.

3.3.1 Thickness of Plating

3.3.1.1 Class 1 – Unless otherwise specified, the minimum thickness of Class 1 nickel plating shall be as specified in Table 1 on any visible surfaces, which can be touched by a ball 0.75 inch in diameter.

3.3.1.1.1 Unless otherwise specified, the minimum nickel plating for ferrous materials or for zinc-based alloys shall be Grade C. Unless otherwise specified, the minimum nickel plating copper and copper alloys shall be Grade D. If the maximum thickness for Grade A is not specified in the contract, order or applicable drawing, the thickness shall not exceed 0.002 inch on all visible surfaces which can be touched by the 0.75-inch diameter ball.

Nickel Plating Services to ASTM B689

Type 1 – Nickel Deposits Plated from Solutions Free of Brighteners Hardeners or Stress Control Additives

Type 2 – Nickel Deposits Plated from Solutions Containing Sulfur or Other Co-deposited Additives

Type 3 – Nickel Deposits Containing Dispersed Submicron Particles such as Silicon Carbide, Tungsten Carbide or Aluminum Oxide to Increase Hardness or Wear Resistance

Classes – Class indicates minimum deposit thickness in microns (µm). e.g. Class 5 is a deposit of 5µm minimum thickness.

Additional Nickel Plating Resources

Nickel Coatings for Electronics:

Without nickel and without coatings, you would have no cell phone. Nickel is essential for any battery (Li-ion, Ni metal hydride, Ni-Cd). It makes lead-free solder possible while also preventing electromagnetic interference and corrosion. Without Nickel, your cell phone would quickly become a useless piece of electronic junk.

Nickel Coatings for Automotive:

Electroless nickel and electrolytic nickel coatings are essential in the automotive market. Electroless nickel is the first choice for protecting critical materials from corrosion in harsh environments, such as in automotive fuel systems, turbochargers, transmission parts and braking systems.

Nickel Coatings for Aerospace:

Nickel coatings are used to improve the physical properties such as wear resistance, heat resistance or corrosion resistance, and to restore the dimensions of undersized parts. The properties and appearance of electrodeposited nickel are used to meet the specific needs for a variety of industries such as the aerospace industry.

WHAT TYPE OF NICKEL PLATING SHOULD I USE FOR MY APPLICATION, WATTS, BRIGHT OR SULFAMATE?

HOW DO I PREVENT DARKENING OF A NICKEL DEPOSIT OVER STEEL WHEN BAKING?