By M. Lindstedt

Gold Plating Services – Delicate and Micro Parts

Gold plating services within the medical, electronic or telecommunications markets often involves the application of gold deposits on very small or micro parts. In these industries, there is an on-going emphasis on Swiss and micro machining of smaller and

Gold Plating – Ultrasonic Cleaning of Parts

Ultrasonic cleaning is a process that utilizes sound energy to create cavitation of microscopic bubbles on the surface of a part. This mechanical energy combined with the thermal and chemical cleaning effect of ultrasonic cleaning solution makes for an extremely powerful cleaning tool. Ultrasonic cleaning prior to gold plating of delicate parts – especially those with small ID holes and features – is critical to remove cutting oils, shop dirt and debris from the surface of the parts. AP utilizes various ultrasonic cleaning techniques generated from both piezoelectric and magnetostrictive generators for a full range of cleaning applications.

Gold Plating – Proper Process Tooling

The process method and tooling needs to match the part to be gold plated. Several methods to plate micro parts can be used:

- MPM Barrel – Minimum Part Movement barrel technology is a proprietary barrel plating technology which minimizes the ability of the parts to tumble and interlock over one another. Advanced Plating Technologies helped pioneer this plating technology with Hardwood Line Manufacturing Co. – the premier hardware manufacturer in the plating industry. MPM allows for barrel plating of long/narrow pins and components often found in gold plating within the telecom or interconnect industries.

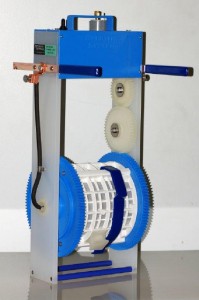

- Vibratory Barrel – Vibratory plating originated in Switzerland with roots in the Swiss watch industry. A vibratory barrel utilizes mechanical vibratory energy to move parts over an electrode bed during plating. The vibratory energy also helps transfer plating solutions into the ID of small inner diameters during plating making this gold plating method an excellent choice for interconnect components such as female sockets where the functional area is in the ID of the part.

Gold Plating – Rinsing, Drying and Packaging Proper rinsing is a key tenat of gold plating services for applications in joinability including wire bonding, soldering and laser welding. A sound gold deposit can fail to solder or bond if the surface is contaminated due to poor rinsing. As such, proper rinsing of gold plated parts – especially small and micro parts – is a critical step in the process. Use of multiple high-quality water counter flow rinses, ultrasonic deionized water rinses and a final spray rinse of virgin deionized water are all techniques used by Advanced Plating Technologies to ensure the highest cleanliness of the gold plated deposit. Drying in a clean, stainless steel oven in a controlled environment ensures that the residual water fully evaporates from the surface without contamination from the oven itself. Packaging of gold plated parts should be selected to protect the purity of the deposit during storage. Nitrogen bag packaging is a specialized packaging method in which the air within a heat sealed bag is extracted and back-filled with pure nitrogen prior to being sealed. This packaging method protects the parts in an inert nitrogen atmosphere until which time they are used. Sealed nitrogen packaging is the preferred packaging method by Advanced Plating Technologies as it prevents oxidation of underplates such as nickel from propagating to the surface of the gold deposit greatly extending the solderability or wire bonding shelf-life. This is especially critical when dealing with thin gold deposits below 0.00003” per side where oxidation through the gold can occur more readily.

Gold Plating – Inspection