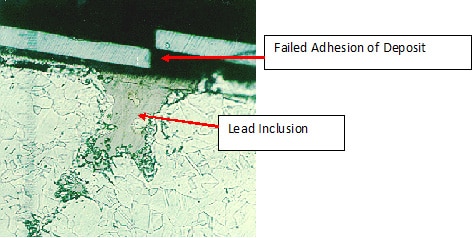

All of the pretreatment systems listed above have a finite life within a plating line based upon the level and severity of usage as a function of the plating load and condition of plated product. If any one of the critical pretreatment chemistries looses its effective strength due to age on the line, poor adhesion of the end deposit can occur. Shown below are two examples of a plated deposit that lost adhesion due to a pretreatment system that failed to remove two common adhesion killers. Figure F.4 shows a lead inclusion on the surface of a 360 leaded brass part that was not removed in the pretreatment system. The result was a failed deposit that can be seen directly over the inclusion:

Figure F.4: Loss of Adhesion due to Lead Inclusion at Surface

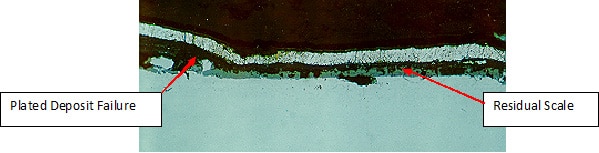

Figure F.5 shows the surface of a heat-treated iron product that was plated over. Evidenced directly below the failed deposit is residual heat treat scale that was not removed by the pretreatment system. Often excessive heat treat scales can only be fully removed from the surface of a part by mechanical methods such as blasting or grinding prior plating.

Figure F.5: Failed Adhesion of a Deposit due to Heat Treat Scale

Although proper maintenance and selection of pretreatment systems is the plater’s responsibility, there are several key areas that buyers can assist the plater to successfully process their product.

a. Provide the Exact Alloy of the Basis Material on all Paperwork including RFQs: The specific alloy of a product can make a world of difference to the plater. For example 260 brass has no lead whereas 360 brass can contain up to 5% lead. Both brasses are very common in usage but each requires a very distinct pretreatment system to ensure proper activation. It is critical to provide the specific alloy UNS to the plater to ensure the parts are pretreated accordingly.

b. Use less tenacious oils wherever applicable: Not all oils are created equal. Organic based oils derived from vegetable and animal sources are generally very easily removed from the surface of materials, whereas waxes and silicon based lubricates can be extremely difficult. The preference of oils used, in order of most preferred to least, is provided below. Whenever functionally and economically feasible, use a lubricant that is more “plater friendly”. Often extremely tenacious oils will require off-line degreasing to remove which can add considerable cost into the price of finishing a product.

- Animal/Vegetable Oils and Fats

- Light Mineral Oils/Water-soluble Coolants

- General Metalworking Lubricants

- Synthetic Oils

- Heavy Grease

- Buffing Compound

- Waxes

- Mold Release Compounds

- Silicon Bases Lubricants

c. Perform heat-treating in an inert environment (bright hardening): Although heat-treating in an inert environment is considerably more expensive that heat-treating in an atmospheric one, the additional cost of preparing the products to be plated can offset the savings. If blasting is required to remove very tenacious heat-treat scales, the cost the plate a product can be up to an entire order of magnitude more than if a scale-free product is received.

d. Use higher quality “plating-grade” materials: Similarly to “c” above, higher-grade materials such as plating-grade sheet product for stamping are by their very nature more expensive. This is because they are manufactured in such a way to ensure a surface condition that is devoid of metallic inclusions and other contaminants that can present extreme adhesion obstacles to platers. Although more dollars may have to be paid up front for quality raw products, the savings in finishing can very rapidly pay for the additional outlay.

Have a current job you need quoted or just have a general question? Send us an email: [email protected].