Silver has extremely high electrical and thermal conductivity – better than that of gold – which has solidified its use in high current power transmission and lower current power connector applications. Silver also is an excellent high temperature lubricant and can be utilized for various high temperature anti-galling applications within the bearing or fastener industries.

The use of silver as an interconnect and electronics finish has been catalyzed by the increased cost of gold and other precious metals. In addition, the reliability of RoHS compliant pure tins has become a design concern due to the risk of tin whisker formation. Silver offers a whisker-free alternative to tin that is fully RoHS compliant.

One of the perceived downsides of silver as a plating finish is its propensity to tarnish. Silver tarnish is not an oxide but is rather silver reacting to the atmosphere containing sulfur or hydrogen sulfide to forming silver sulfide or silver nitrate. The tarnish that forms is somewhat conductive and can be readily removed. In sliding contact applications, silver tarnish is removed by the inherent wiping action of the contact design.

In solderability applications, a light tarnish will not typically affect solderability, however in case where tarnish is greater; a more active flux can be chosen to

Silver plating services have gained popularity in the lead frame industry as well as in LED applications where silver’s optical reflectivity is utilized. Silver is anti-microbial and has been used in the medical, consumer, and water treatment industries for these natural germicidal properties.

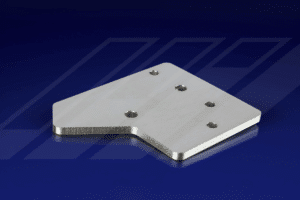

Various types of silver plating services exist from bright, semi-bright, and matte finishes at varying purity levels up to 99.9%. Most specifications contain callouts denoting if the use of an under plate or anti-tarnish is required. The most common specifications called out for silver plating are QQ-S-365 and ASTM B700. In addition to these specifications, Advanced Plating Technologies provides silver plating services to fulfill the most demanding applications including aerospace specifications including AMS 2410, AMS 2411 and AMS 2412 as well as most company specific or corporate specifications.

The engineering properties of silver make it an outstanding finish at a much lower cost than many precious metal finishes. The perceived deleterious effects of tarnish can often be mitigated for many design applications making it an excellent choice for many design applications. A member of Advanced Plating Technologies technical sales staff can assist with designing a finish the meets the specific design requirements of your application.

Blog Authored by Eric Probasco. , Plant Manager