By R. Savija

All specifications for electroplating, whether military, federal, ISO, ASTM or SAE-AMS specifications, have an initial section that contains essential information to be supplied by the purchaser to the electroplater. More times than not, much of this information is omitted from part prints and purchasing documents which opens the door to potential miscommunication and finishing shortfalls. This blog details some of the more common omissions that are discovered by Advanced Plating Technologies’ engineering staff during quoting or contract review of specifying a plating process.

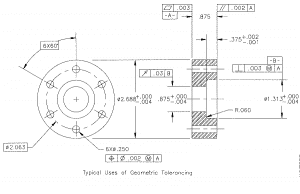

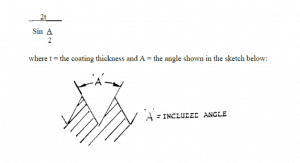

Specification of the plating thickness and tolerance requirements:

Plating thickness varies due to the inconsistent distribution of plating current on an electroplated part. Ionic plating current, like electrical current, takes a preferential path of least resistance with the corners and ends of a part receiving a higher current density and therefore higher plating thickness. If the design of a component requires a very tight plating tolerance, it is important to designate a functional surface where a plating thickness check point can be established. If the plating is specified as 0.0003” minimum and 0.0005” maximum with a specific checkpoint, a plating protocol can generally be developed to consistently meet this requirement. Any specific part dimensional tolerances should be addressed in combination with a plating thickness checkpoint to allow for a combined plating thickness and part dimensional inspection protocol.

Hardness or Strength Requirements

Most electroplating specifications require hydrogen embrittlement relief baking for high strength or hardened steels having a strength greater than 180ksi or Rockwell hardness of 40 HRC or more. In addition, pre-plate stress relief bakes are often required within plating specifications for hardened or cold-worked ferrous materials. Often the hardness of a steel component is not listed on the drawing or purchase order which requires follow up during quoting or contract review. In some cases the hardness of a steel material is not so obvious, such as with music wire used in springs and wire-forms. The purchaser rarely specifies the tensile strength of music wire on the drawing. A closer examination, however of the music wire specifications such as ASTM A228 indicate that all music wire has a tensile strength well above180 ksi which is the strength equivalent of 40 HRc.

Condition of the As-received Material

Surface Roughness

It is a common misconception that electroplating can actually cover-up up surface imperfections on the part and that electroplating can significantly improve surface roughness. In most plating applications, this is not the case and it is generally recommended that the pre-plate surface roughness be slightly better than the desired post-plate surface finish. For example, if a post-plate Ra of 16uin is required, it is generally recommended that a pre-plate Ra of 10-12uin be provided. This is especially true of electroless processes such as electroless nickel that have virtually no “leveling” properties.

Plating Buildup on Threads

Racking Locations

The above points detail just a few commonly overlooked areas that are critical to a successful outcome in a metal finishing process. By carefully reviewing the ordering information listed within most plating specifications, the purchaser can be assured that details critical to a successful plating outcome are detailed at time of quote or purchase. Advanced Plating Technologies is happy to provide guidance along these lines by talking with any of our estimating or process engineers. Visit the contact us section of our website to submit a plating inquiry or general question regarding specifying a plating process. Our Technical Library contains common plating topics, specifications and white papers specific to the plating process.