Advanced Plating Technologies is committed to developing the most advanced surface engineering solutions for ammunition components used in critical defense, law enforcement and military applications.

Building upon the advancements of APT’s Ducta-bright 7a® nickel technology – Black-TPD® (Tactical Performance Defense) provides key deposit properties previously unavailable with any coating systems used within the ammunition industry.

Black-TPD® couples the unmatched deposit durability, reloading capacity and ductility of APT’s Ducta-bright 7a® nickel with a proprietary Black-TPD® alloy. The result is a duplex coating system with unsurpassed corrosion resistance, dry film lubricity with a premium, liquid-black appearance.

The premium appearance of Black-TPD® is an excellent accompaniment to the significant performance improvements that the coating affords.

Black-TPD® Plating – Duplex Coating Technology

Traditional nickel plating of shell casings has been used for decades to avoid the green corrosion known as verdigris from occurring when classic revolver calibers were stored in leather utility pouches or ammo loops traditionally used by law enforcement. Nickel plating allowed cartridges to be stored over a much longer period of time without degradation of the brass.

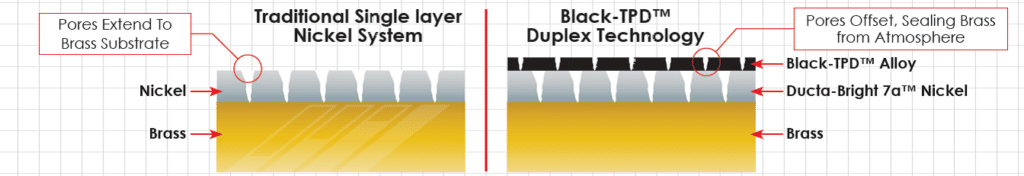

However, traditional single layer systems such as nickel have limitations in their capabilities. Nickel deposits provide corrosion resistance by forming a barrier between the base material and the destructive effects of atmospheric moisture and corrosives such as human sweat. However, nickel must be deposited in a very thin layer to avoid fitment and functionality issues with ammunition components. Thin nickel deposits have intrinsic porosity which allows penetration of corrosives to reach the basis material. Black-TPD® addresses this performance limitation by applying a secondary layer over the nickel which reduces the overall deposit porosity resulting in greatly improved corrosion resistance over a nickel system alone.

Today’s ammunition engineers are tasked with designing components for critical service and defense applications that must function when it counts after years of harsh field exposure. Black-TPD® provides outstanding corrosion performance through duplex coating technology unmatched by any single layer system ensuring consistent and reliable function when lives and personal security are at stake.

A plated layer acts as a barrier between the corrosive effects of the atmosphere and the basis material. Any plated deposit will have intrinsic porosity that can only be reduced in single-layer systems by increasing the thickness of the deposit. However, as plating thickness increases, the ability to hold tight dimensional tolerances become increasingly challenging. Duplex systems employ two plated layers in which the pores of the two deposits are not in alignment, which greatly reduces the porosity of the overall plated system. This allows for improved corrosion resistance consistent with much thicker single-layer systems while maintaining the tight dimensional tolerances that today’s modern firearm designs demand.

Black-TPD® Plating – Dry Film Lubricity

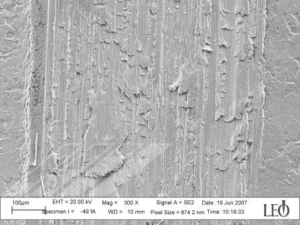

Today’s firearms cycle faster, more often and with higher chamber pressures than ever before. The expanded use of +P and +P+ loads to push the performance window of compact weapons has further pushed the limits of traditional designs. Unlike firearm coatings, which can rely on oil and other lubricants for proper function, ammunition must rely on unlubricated or dry film methods to perform reliably. Most traditional ammunition component materials such as brass, lead and copper are softer materials that have a higher coefficient of friction and can gall during cycling as shown in Figure 1. The use of nickel plating on casings has helped to address this issue by providing a harder surface layer to reduce the tendency of galling during chambering and cycling of actions.

Black-TPD® takes the wear benefits of nickel plating to the next level by combining a proprietary TPD-alloy over APT’s Ducta-bright 7a® nickel plating. The TPD-alloy is a multi-metal codeposit specifically engineered to provide an optimal ratio of hardness and lubricity offering enhanced dry-film lubricity over that of nickel alone. The penultimate Ducta-bright 7a® nickel layer provides a nickel base that has been optimized to maximize the ductility, bond strength and reloading capacity of the nickel deposit. The result is a coating system with unsurpassed dry film lubricity ensuring the smoothest and most reliable feeding in all actions of firearm that will not crack or flake even in the highest pressure +P or +P+ loads.

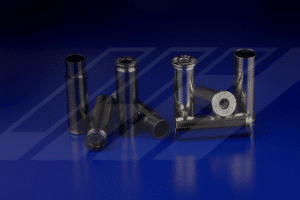

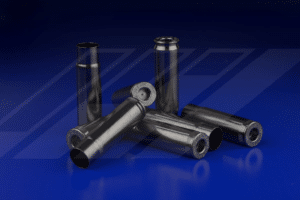

Black-TPD® Plating – A Liquid-Black Finish

Black-TPD® enhances the appearance of any ammunition component with a deep, liquid-black finish that provides visual differentiation as a premium finish at point of purchase. It can be deposited over nearly any basis material including brass, copper, lead, steel and aluminum and will provide a consistent and uniform appearance regardless of basis material. It can be applied to ballistic tip projectiles providing an enhanced contrast between the tip and the bullet jacket.

The lustrous, black appearance of Black-TPD® makes critical defense ammunition look as good as it performs and helps to differentiate the performance benefits of a premium line of ammunition within a diverse product offering. Black-TPD® provides a stealthy black look making it an excellent complement to tactical applications for semi-auto calibers such as 380-Auto, 9mm, 40S&W or 45ACP as well as long-gun applications including 5.56, 7.62 and the popular 300 AAC Blackout