Choosing Types of Powder Coating for any Industry

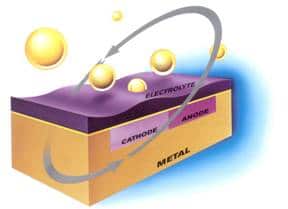

Powder coating is a surface finishing option that applies a relatively thin film to provide excellent corrosion protection and chemical resistance in a highly cosmetic manner. While parts are often designed with specific colors, gloss, and textures – the types of powder coating are often overlooked, yet a critical component to every powder coating job.

Powder coatings are applied in a variety of types. Each resin system has specific attributes that are able to better suit needs of specific environments. Some of the most popular types of powder coating include: Epoxy Powder Coatings; Polyester Powder Coatings; Hybrid Powder Coatings.