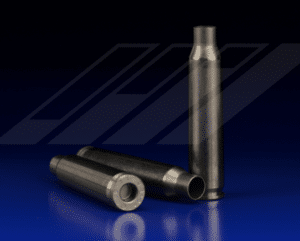

Eclipse-TPD® (Tactical Performance Defense) is the most advanced low reflectance coating available today for ammunition components. Eclipse-TPD® provides a smoke-black, matte appearance that is ideal for use where low light reflectivity is a tactical requirement. Eclipse-TPD® utilizes duplex coating technology with a molecular sealer to offer the highest corrosion performance and lubricity of any ammunition coating available today.

Advanced Plating Technologies pioneered the use of duplex coating technology within the ammunition industry with our Black-TPD® process. This industry-leading finish utilizes an alloy topcoat plated over APT’s benchmark Ducta-Bright 7a® nickel to provide enhanced lubricity and corrosion performance

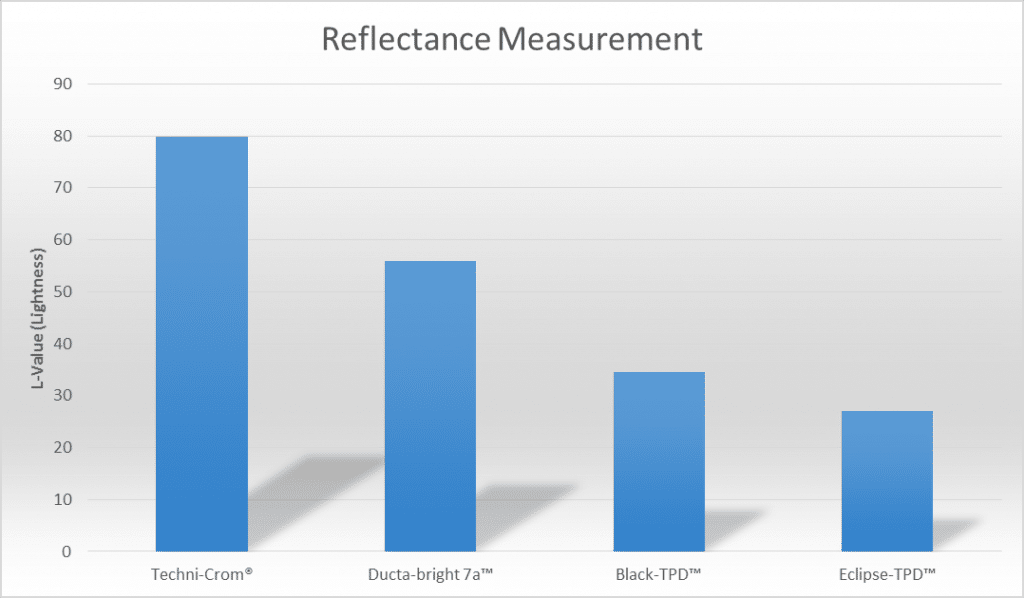

The matte, smoke-black color provides a significant tactical advantage by dispersing light within the visible range. There is no other finish today that couples the lubricity and corrosion performance benefits with the low reflectance tactical advantage of Eclipse-TPD®.

Eclipse-TPD® – Plating Molecular Enhanced Duplex Technology

Advanced Plating Technologies pioneered the use of duplex coating technology within the ammunition industry with Black-TPD® process. This industry-leading finish utilizes an alloy topcoat plated over APT’s benchmark Ducta-Bright 7a® nickel to provide enhanced lubricity and corrosion performance. In either process, the topcoat reduces the overall porosity of the coating system, providing greatly improved corrosion resistance over that of a single layer nickel system.

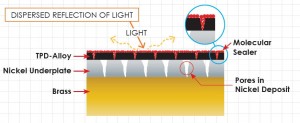

This finish takes duplex technology to the next level with a proprietary molecular sealer that both disperses reflected light and significantly enhances the corrosion resistance of the duplex process. The molecules of the Eclipse-TPD® sealer embed within the pores of the TPD-alloy topcoat, fully sealing the basis material from the destructive effects of atmospheric moisture and corrosives such as human sweat. The combination of a duplex plated layer with the molecular sealer of the Eclipse-TPD® process virtually eliminates a corrosive path between the atmosphere and the basis material. Simply put, there is no coating system available today that can exceed the corrosion performance of Eclipse-TPD® – period.

What is Duplex Technology with Eclipse-TPD®?

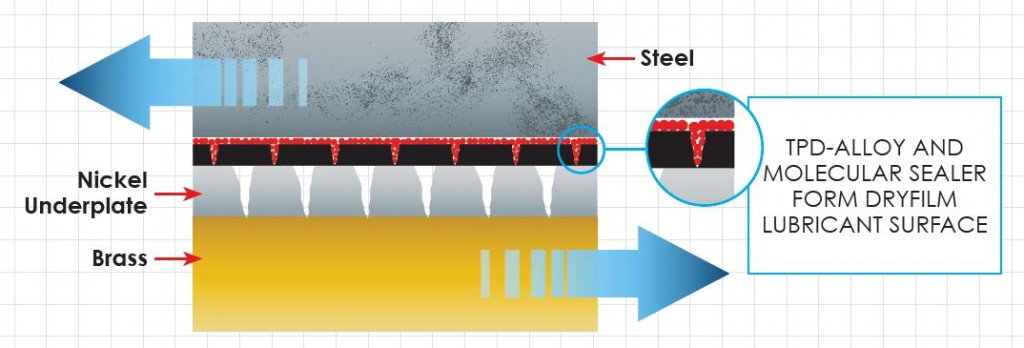

A plated layer acts as a barrier between the corrosive effects of the atmosphere and the basis material. Any plated deposit will have intrinsic porosity that can only be reduced in single-layer systems by increasing the thickness of the deposit. However, as plating thickness increases, the ability to hold tight dimensional tolerances becomes increasingly challenging. Duplex systems employ two plated layers in which the pores of the two deposits are not in alignment, which greatly reduces the porosity of the overall plated system. This allows for improved corrosion resistance consistent with much thicker single-layer systems while maintaining the tight dimensional tolerances that today’s modern firearm designs demand.

__________________________________________________________________________________________________________________________

Eclipse-TPD® Plating – Enhanced Dry Film Lubricity

Today’s firearms function at higher chamber pressures and at faster cycle rates than ever before. The expanded use of +P and +P+ loads to push the performance envelop of compact firearms has increased the importance of proper surface engineering of both firearms and ammunition components. Most traditional ammunition materials such as copper, lead and brass are softer materials that have a higher coefficient of friction and can gall during metal-on-metal wear. Unlike firearm coatings, which can rely on oil and lubricants for proper function, ammunition must rely on unlubricated or dry film methods to reduce friction and improve function in modern semi-automatic and automatic actions.

Eclipse-TPD® utilizes a TPD-alloy topcoat that is a multi-metal codeposit specifically engineered to provide an optimal ratio of hardness and lubricity to provide enhanced dry film lubricity over that of nickel alone. The TPD-alloy is further enhanced with a proprietary molecular sealer that embeds in the pores of the alloy, acting as a dry film lubricant to produce a surface engineered comprehensively for metal-on-metal lubricity. Eclipse-TPD™ provides a surface coating that will cycle smoothly and reliably in any action of firearm under the worst of environmental conditions. The performance of the coating will not degrade even during extended storage, for reliable service when in counts.

Eclipse-TPD® Plating – Low Reflectance Coating for Tactical Applications

Eclipse-TPD® provides the lowest reflectance of any coating within the ammunition industry today. The ability of the coating to scatter light provides a tactical advantage for any application where low visibility is a design consideration. Eclipse-TPD® can be applied to any basis material including brass, copper, steel and aluminum and will produce a similar finish regardless of the basis material. It can be applied as well to ballistic tip projectiles, providing an enhanced visual contrast between the tip and bullet jacket.

The matte, smoke-black color of Eclipse-TPD® provides a significant tactical advantage by dispersing light within the visible range. There is no other finish today that couples the lubricity and corrosion performance benefits with the low reflectance tactical advantage of this finish. The consistent cosmetic appearance of Eclipse-TPD® is an excellent accompaniment to the significant performance improvements that the coating affords.