Advanced Plating Technologies offers a range of proprietary Ammunition, Firearm and Optic finishes engineered to ensure critical consumer, law enforcement and military defense components exceed demanding design requirements. Each of these finishes has been developed by Advanced Plating Technologies’ engineering and chemical experts with input and test feedback from our key customers within these industries. With nearly eight decades of surface engineering experience, APT continues to push design limits to develop innovative coatings that help our customer’s parts perform better, last longer and work flawlessly when it counts.

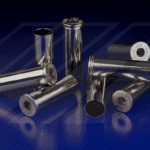

Ducta-Bright 7a® Nickel Plating of Shell Casings

Ducta-Bright 7a® Nickel the superior, ductile nickel plating process for plating of components that must be sized, crimped or otherwise formed post plate. Ducta-bright 7a® Nickel was developed by APT in 2009 to meet the specific needs of the self-defense and law enforcement ammunition market. Today it is the top choice of industry-leading ballisticians for critical self-defense, law enforcement and defense ammunition components. Ducta-bright 7a® Nickel will not crack, flake or peel when sizing, canneluring, loading or reloading. Nickel plating of shell casings with Ducta-bright 7a® provides several key benefits including improved feeding in all actions of firearms, enhanced corrosion resistance, visibility in low-light chamber checks and ease of cleanup during reloading.

Black-TPD® Plating

Black-TPD® is a proprietary coating engineered specifically for the premium self-defense ammunition market. Black-TPD® couples the unmatched deposit durability, reloading capacity and ductility of APT’s Ducta-bright 7a® Nickel with a proprietary Black-TPD® alloy topcoat. The result is a duplex coating system with unsurpassed corrosion resistance, dry film lubricity with a premium, liquid-black appearance.

Eclipse-TPD® Plating

Eclipse-TPD® produces a smoke-black, matte appearance that is ideal for use where low light reflectivity is a tactical requirement. Eclipse-TPD® utilizes duplex coating technology coupled with a proprietary molecular sealer to provide the highest corrosion performance and lubricity of any ammunition coating available today. Eclipse-TPD® is the result of fifteen years of ammunition coating engineering and is the most advanced component coating available in the ammunition industry today.

Dura-Nickel HP+®Plating Services

The performance advantages of Dura-Nickel can be leveraged within a range of ammunition applications including hybrid or steel case designs and improved corrosion resistance over traditional nickels on standard brass or gilding metal. Dura-Nickel HP+® is a more cost-effective coating that can be used in most applications where radii of the components can be maintained at 0.020” or greater. Dura-Nickel A1™ is a next-generation coating within the Dura-Nickel family that provides improved corrosion resistance, especially in applications where sharp tips and radii of components are less than 0.020”.

Tacti-Black® Composite

Tacti-Black® Composite is the first hybrid coating that breaks the narrow silos of traditional coatings by allowing a designer to specify unique and dissimilar properties on the same part. Tacti-Black® Composite couples Advanced Plating Technologies’ proprietary black electroless nickel with a selective polymeric coating that provides ergonomic characteristics not previously available with a single coating. The polymer zone of Tacti-Black® Composite is offered in a range of colors including Jet Flat Black (JFB), Flat Dark Earth (FDE) or Olive Drab Green (ODG). It is also available in a smooth or textured finish to customize the ergonomics at the functional touch points.

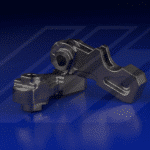

Tacti-Black® Electroless Nickel Firearm Finishes

Tacti-Black® electroless nickel plating on firearm components offers several improvements over other black finishes available. Greater corrosion resistance, a more consistent black finish regardless of substrate, enhanced lubricity as well as maintaining tight tolerances during the plating process. Tacti-Black® HP+ is unmatched in consistency and lubricity for critical action components including as sears, hammers, triggers, extractors and pins. APT is ITAR registered and holds a type 10 FFL (Federal Firearms License) to handle processing of serialized firearm components.

Copper Plating of Bullets and Projectiles

Advanced Plating Technologies provides heavy-build copper plating of lead, steel, tungsten or aluminum cores/projectiles as well as frangible powdered metal cores for tactical or training applications. APT pioneered the use of proprietary high-speed copper chemistries paired with ultra-efficient Spray-Thru™ barrels to provide heavy build copper plating of bullets and projectiles to thicknesses exceeding 0.020-inches per side. APT can provide either plate-to-gauge (size) or plate-to-weight (grain weight) to meet the specific needs of the projectile design.