Silver Plating Services

APT offers a wide range of silver plating services including matte, semi-bright and bright silver deposits. Deposit purity of up to 99.9% is available for applications that demand the highest conductivity or high temperature lubricity. Silver plating has excellent anti-galling, thermal and electrical conductivity properties as well as outstanding solderability. Silver is not a truly precious metal in that it can form sulfur compounds commonly referred to as tarnish. However, these sulfur compounds are very conductive and do not significantly degrade the performance of silver unlike other metal oxides. In addition, APT offers various anti-tarnish inhibits (Class S and T) and can custom engineer inert packaging solutions using silver saver products and nitrogen sealed packaging to avoid silver tarnishing in storage.

Silver Plating of Copper Alloys

Silver plating of copper or copper alloys is a highly functional finish for transferring heat and electricity utilized across a wide breath of industries. Silver has been applied since late 1800s on electrical switchgear and other components that pass electrical current. In recent years silver plating of copper electronic components including connectors and terminals has grown rapidly within the electronic, automotive and electric vehicle (EV) markets. Silver plating has many unique properties that make it desirable for these applications. The primary reason is that silver has the highest electrical and thermal conductivity of any metal, which facilitates the efficient transmission of electricity and heat.

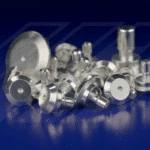

Silver Plating of Stainless Steel

Silver plating on stainless steel and other high temperature alloys such as Inconel®, Nitronic® and Hastelloy® is a common silver plating service for nuts, fasteners, slip-rings, thrust-washers, bushings and other bearing surfaces that benefit from the lubricity of silver at high temperatures allowing parts to exhibit anti-galling and anti-seizing properties. Silver is a unique precious metal that exhibits many desirable properties for utilization across a broad range of engineered applications. Of all metals, silver has the highest thermal conductivity, electrical conductivity, and optical reflectivity in the visible portion of the electromagnetic spectrum; silver has outstanding temperature resistance with a melting point of 962° C (1763° F).

Difference between Gold vs Silver Plated Connectors

When it comes to plating electrical components such as connectors and contacts, gold and silver are two common electroplating processes that produce highly reliable and conductive connections. However, there are advantages and disadvantages between silver and gold plating services. Both gold and silver are highly conductive and corrosion resistant; however, silver will form a sulfide compound (tarnish) and gold can be a costly option. In this article, we’ll be discussing the difference between gold and silver connectors and when one coating might be preferable over the other.