Tacti-Black® Composite – A Hybrid Finish that Couples Dissimilar Coating Properties on the Same Part

We do not service personal or decorative projects

Why do coatings exist? At the foundational level, coatings are applied to parts to impart properties that the base material does not intrinsically have. Coatings are applied to improve corrosion resistance, hardness, lubricity and wear resistance while also providing improved cosmetics or reduced visibility/reflectivity. Most coatings provide a limited range of properties; for example, a coating may be hard and wear resistant, but it cannot at the same time provide texture and insulate from cold. For many parts such as hardware components, having a narrow range of coating properties is acceptable. However, for more complex applications, having a narrow range of coating properties limits the design and functionality of the end product.

Advanced Plating Technologies has an active Federal Firearms License allowing for the processing of serialized firearm components such as slides or uppers. APT is also ITAR registered for critical defense applications where control of documentation and processes is critical.

Our firearms finishing processes are forged around our ISO 9001:2015 quality management system, ensuring firearms finishing that meets specification and is consistent from lot to lot.

Tacti-Black® Composite – A Finish that Breaks Traditional Coating Conventions

With today’s complex firearm and optic designs there are an increasing number of applications where a part may need very dissimilar properties on separate features of the component. For example, a laser optic battery cap may need an electrically conductive coating on the interior that ensures current flow in harsh environments. In contrast, the outside of the cap requires a coating that electrically insulates and provides a textured grip in a color that closely matches the anodized optic housing. Until recently, a dichotomy of properties such as this could not be provided by a single coating.

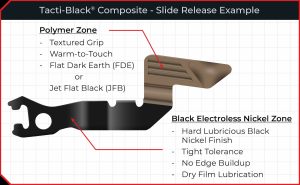

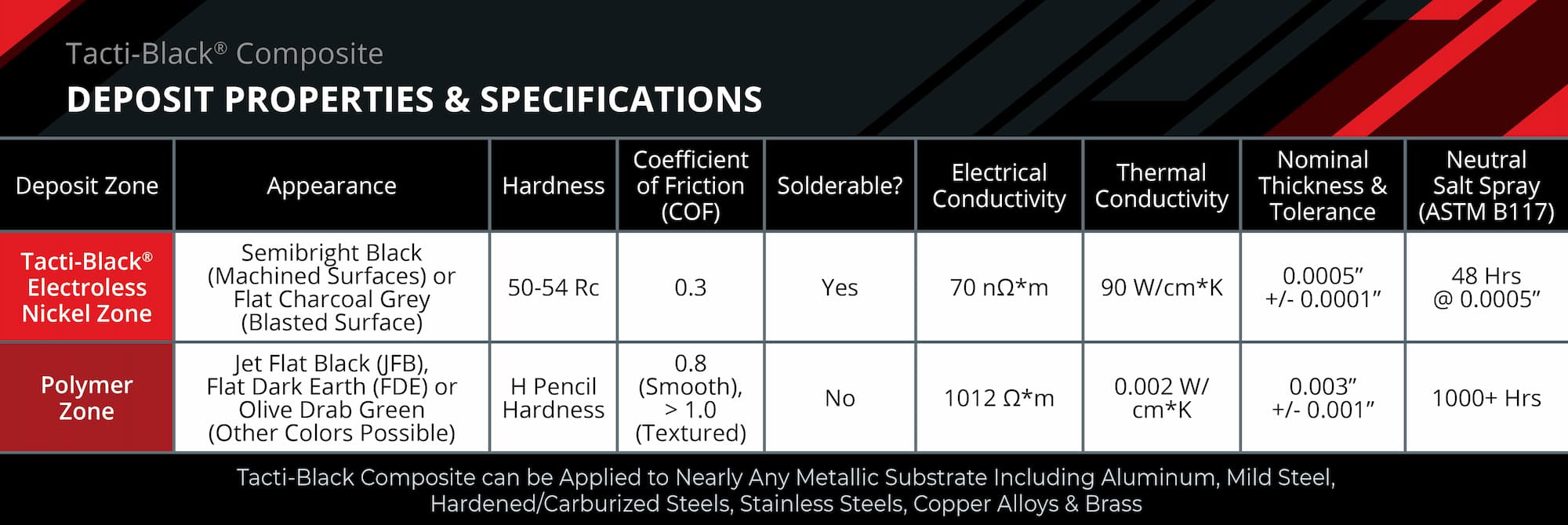

Tacti-Black® Composite is the first hybrid coating that breaks the narrow silos of traditional coatings by allowing a designer to specify unique and dissimilar properties on the same part. Tacti-Black® Composite couples Advanced Plating Technologies’ proprietary black electroless nickel with a selective polymeric coating that provides ergonomic characteristics not previously available with a single coating. The polymer zone of Tacti-Black® Composite is offered in a range of colors including Jet Flat Black (JFB), Flat Dark Earth (FDE) or Olive Drab Green (ODG). It is also available in a smooth or textured finish to customize the ergonomics at the functional touch points. The ability to customize the features of Tacti-Black® Composite make it the ultimate engineered finish for today’s critical tactical and defense applications.

Tacti-Black® Composite Case Study 1: IR/Laser Optic Battery Cap

A large defense optic OEM had a design challenge to provide a coating that would be electrically conductive on the interior of a battery cap, ensure a conductive path even when exposed to moister/salt water and not reflect during battery swaps. The exterior of the cap had to be textured to facilitate removal of the cap when wet or frozen and had to resist over 1000-Hr salt spray while matching the FDE of the existing anodized optic. Tacti-Black® Composite in textured FDE met all design requirements and helped the OEM fulfill a major contract

Tacti-Black® Composite Case Study 2: Firearm Low-Profile Slide Release