Vapor Degreasing Services

Advanced Plating Technologies, a Milwaukee, Wisconsin company, provides comprehensive vapor degreasing services on any metallic substrate as well as a range of polymers or phenolics. Vapor degreasing is an excellent method to remove gross machining oils, mild die or mold release agents, drawing lubricants and other surface contaminants. In addition, vapor degreasing services can be coupled with additional cleaning methods including electrocleaning and ultrasonic cleaning services to provide a custom cleaning protocol tailored to the specific application.

Vapor degreasing services provide an excellent alternative to aqueous washing systems as they retain the dissolved organics within a solvent rather than an aqueous suspension. Once expended, the solvent can be recycled for reuse, making it an environmentally sound method of parts cleaning. Our company often employs ultrasonic cleaning of parts prior to subsequent metal finishing operations such as plating or powder coating to improve the processing consistency regardless of the as-received soil loading of the components.

Advanced Plating Technologies’ vapor degreasing services eliminate the environmental concerns of treating water from traditional aqueous washing systems. In addition, many companies have found an economic advantage with outsourcing the cleaning requirements of their manufacturing process with Advanced Plating Technologies by utilizing our vapor degreasing services.

Vapor Degreasing Service – Vapor Degreasing Properties

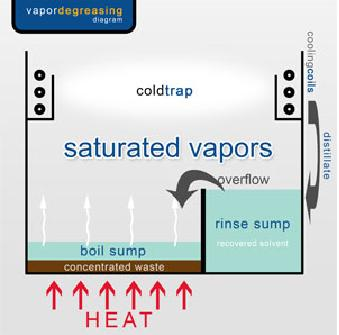

Vapor degreasing utilizes both liquid and vapor forms of an organic solvent to remove organic matter from the surface of a part. Within a commercial vapor degreasing unit there is a heated liquid sump of solvent that produces a vapor zone above the liquid solvent level. An upper cooling jacket maintains the vapor solvent within the degreasing unit.

unit there is a heated liquid sump of solvent that produces a vapor zone above the liquid solvent level. An upper cooling jacket maintains the vapor solvent within the degreasing unit.

The work piece is lowered into the heated solvent sump where ultrasonic generators can be used to enhance the overall cleaning action. Once removed from the solvent sump, the work piece receives a “virgin” solvent cleaning via suspension within the vapor cloud above the liquid sumps. The vaporized solvent provides an excellent final stage of cleaning since it is fully devoid of dissolved organics due to its vaporized state. This “vapor-only” cleaning effect makes vapor degreasing a more reliable and superior cleaning process than many aqueous-based methods of degreasing.

The specific vapor degreasing solvent employed varies upon the application. Advanced Plating Technologies typically utilizes an n-propyl bromide solvent (NPB) for the majority of our vapor degreasing services due to its excellent performance and environmental acceptance. Demanding applications of vapor degreasing services such as parts laden with polishing compounds or grease may require the use of an alternate solvent or multiple cleaning steps.

Vapor Degreasing Services – Advanced Plating Technologies’ Capabilities

Specifications:

Most Company Specifications

Substrates Plated On:

Ferrous: All Ferrous Alloys Including Mild Steel, Stainless Steels, Hardened Steels & Tool Steels

Cuprous: All Cuprous Alloys Including Pure Copper, Copper Alloys Including Tellurium & Beryllium, Brass, Nickel-Silver

Aluminum: All Aluminum Alloys Including Wrought, Cast and Proprietary Alloys (MIC-6)

Exotics: Inconel, Pure Nickel (Nickel 200), Cobalt-Chrome (MP35N), Kovar, Monel, Hastalloy, Monel, Lead

Zinc: All Cast or Wrought Alloys

Part Size Limitations:

40 Inches x 60 Inches x 14 Inches

Up to 300 lbs

Methods:

Rack

Basket/Tray

Sheet Product (Chemically Milled/Etched Sheets)

Segmented Strips (Frets)